Plant WHS Regulations: A Summary

Plant (in particular, mobile plant) is the one of the leading causes of death in the workplace. Keep reading to learn the plant WHS regulations in Australia.

Plant (in particular, mobile plant) is the one of the leading causes of death in the workplace. Keep reading to learn the plant WHS regulations in Australia.

Definition of Plant

The definition of plant from the WHS regulations includes “machinery, equipment, appliances, containers, implements and tools…”.

Some examples could be:

- Mobile plant (e.g. forklifts)

- Vehicles

- Power tools

Hand tools that are not powered (e.g. hammers) are not included in this definition.

Hazards Associated with Plant

Many types of plant pose serious risks to health and safety. If left uncontrolled, these hazards can result in serious or fatal injuries.

Hazards posed by plant can include:

Hazards posed by plant can include:

- Crush / Pinch Injuries

- Vibration

- Suspended Loads (for lifting plant)

- Electrocution / Electrical Hazards

- Rollover (for mobile plant)

- Vehicle Collision

- Burns

- Hearing Damage

- Fire

Legislative Requirements

Plant in the WHS Act

The primary legal requirements for plant are outlined in the act, and these are:

- WHS Act s(19)(3)(b) – Duty to Provide Safe Plant

- WHS Act s(19)(3)(d) – Duty to Ensure Safe Use of Plant

The following sections could also apply to plant:

- WHS Act s(19)(3)(c) – Duty to Provide Safe System of Work

- WHS Act s(19)(3)(f) – Duty to Provide Adequate Information, Training, Instruction and Supervision

Plant in the WHS Regulations

There are many sections in the regulations that relate to PCBUs that manage or control plant, including:

- WHS Regulation s(203) Management of risks to health and safety

- WHS Regulation s(204) Control of risks arising from installation or commissioning

- WHS Regulation s(205) Preventing unauthorized alterations to plant

- WHS Regulation s(206) Proper use of plant and controls

- WHS Regulation s(207) Plant not in use

- WHS Regulation s(208) Guarding

- WHS Regulation s(209) Guarding and insulation from heat and cold

- WHS Regulation s(210) Operational controls

- WHS Regulation s(211) Emergency stops

- WHS Regulation s(212) Warning devices

- WHS Regulation s(213) Maintenance and inspection of plant

There are also legal duties for PCBUs that design, import or supply plant are, including the following.

- WHS Act s(22) Duties of persons conducting businesses or undertakings that design plant, substances or structures

- WHS Act s(23) Duties of persons conducting business or undertakings that manufacture plant, substances or structures

- WHS Act s(24) Duties of persons conducting businesses or undertakings that import plant, substances or structures

- WHS Act s(25) Duties of persons conducting businesses or undertakings that supply plant, substances or structures

- WHS Act s(26) Duties of persons conducting businesses or undertakings that install, construct or commission plant or structures

In general, PCBUs are required to manage the risk of plant ALARP.

Managing Risk of Plant Code of Practice

There is a code of practice Managing risks of plant in the workplace. This code includes guidance on risk management, recommended controls and record keeping.

Australian Standards

There are Australian Standards for many types of plant. In general, businesses should ensure that their plant meets the requirements outlined within the standard. If you have purchased the plant in Australia, it should meet the Australian Standard. PCBUs need to be cautious when buying plant from overseas (e.g. importing plant) as often these machines don’t meet Australian Standards.

Safe Work Method Statements

In the construction industry, use of mobile plant is considered “high-risk construction work”. We have a detailed guide on SWMS and high-risk construction work.

Plant Risk Assessments

Plant risk assessments are commonly completed to assist in the management of plant risks. We supply various risk assessment templates in our free resources section – Plant Risk Assessments.

How to Control Plant WHS Risks

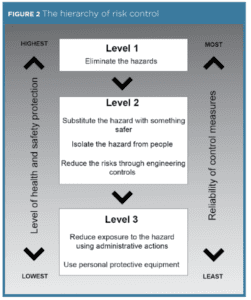

As with all WHS risks, the hazard should be managed in accordance with the Hierarchy of Controls, with levels of protection higher in the hierarchy preferred over lower levels.

Some potential risk control measures for managing WHS hazards associated with plant in the workplace include:

Some potential risk control measures for managing WHS hazards associated with plant in the workplace include:

- Providing Information – Ensuring workers are provided with the operator’s manual, SWMS / SOPs and risk assessments.

- Consulting with Workers – Ensuring workers are consulted in relation to the risks posed by plant and allowing workers to take part in the risk management process.

- Instruction, Supervision and Training – Ensure workers have High-Risk Work Licenses where required or RTO / VOC training for other plant and adequate supervision is provided for new or inexperienced workers.

- Maintenance – Ensuring plant is well maintained and no unsafe or illegal adjustments are made.

- Guarding – Ensuring adequate guarding is installed.

- Emergency Stops – Ensuring emergency stops are installed.

- Warning Devices – Ensuring warning devices are installed (e.g. flashing lights, reverse beepers).

- Isolation Points – Ensuring isolation points are provided and functional.

- Storage – Ensuring plant is stored in a safe manner.

- Spotters – Ensuring spotters are provided when plant is operating in high-traffic areas or near power lines

FAQ

What is plant?

Plant in the context of workplace safety refers to machinery, equipment, appliances, containers, implements, and tools, including their components or anything connected to them.

What is not plant?

Plant that relies exclusively on manual power for its operation and is designed to be primarily supported by hand, for example a screwdriver, is not covered by the WHS Regulations.

What hazards are involved in plant operation?

Many hazards exist in plant operation, for example

- Moving parts

- Moving plant

- Equipment failure

- Electrical, hydraulic or mechanical energy

- Rollover

- Flying debris

Do you need a license to operate plant or equipment?

Legally, you only require a license to operate “high-risk plant”. For other types of plant or equipment, the level of training provided should be suitable considering “the nature of the work, the nature of the risks and the control measures required” – from WHS regulations. That is, for plant that poses no or minimal risks, there may be very little training required. As the risks of the plant increases, the requirement for training also increases.

Article Sources and Further Reading

- Model Code of Practice: Managing risks of plant in the workplace (Safe Work Australia) <https://www.safeworkaustralia.gov.au/doc/model-code-practice-managing-risks-plant-workplace>

- Mobile Plant (Work Health and Safety QLD) <https://www.worksafe.qld.gov.au/safety-and-prevention/hazards/workplace-hazards/construction/mobile-plant>