Free Brake Press SOP (Safe Operating Procedure) Template

Download our free Brake Press SOP Template:

*For internal use only. Not for resale or redistribution. By downloading, you agree to our Free Resources Licensing Agreement.

Purpose of Document

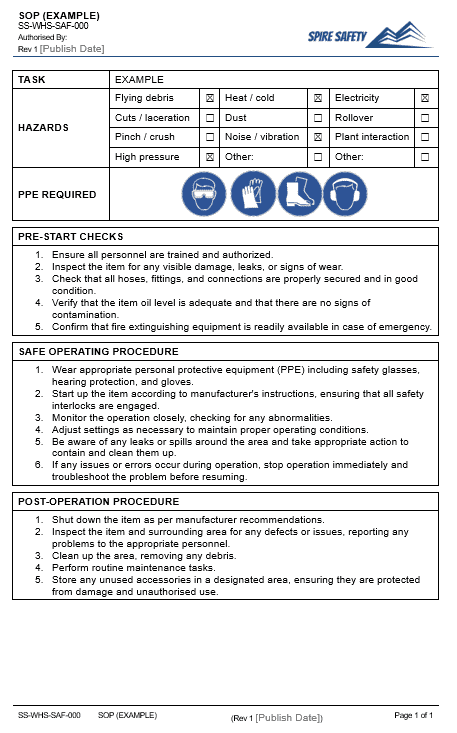

Brake Press SOPs outline a safe operating procedure for brake press use. SOPs can also be used as a training and induction document. The primary goal is to protect workers from injury or illness by outlining a safe system of work and providing adequate training and instruction. This form is broadly aligned with AS45001:2018.

How to Use

This Brake Press SOP should be communicated to workers before they complete the task. A hard copy can also be displayed in the workplace or provided at the workface. You can also use this document during the induction or onboarding process.

NOTE: This document is a template only and it must be customised for your business. Other aspects that need to be considered include, but are not limited to, ensuring that:

- Relevant legal requirements have been met,

- Workplace specific risks are identified and managed, and

- Workers are consulted with during the customisation / review process.

When to Use

Workers should read and agree to comply with Brake Press SOPs prior to operation within your business. They can also be used for refresher training periodically.

Who Should Use

Brake press SOPs should be developed by a competent person. The SOP is then read and followed by the worker completing the task. New workers should also read and understand the SOPs during the induction or onboarding process.

Legal Considerations

There is no specific legal requirement to have a documented Safe Operating Procedure (SOP). However, it is best practice, as having SOPs can assist in meeting general legal duties, including:

- s(19)(3)c WHS Act – Duty to Provide Safe Systems of Work

- s(19)(3)d WHS Act – Duty to Ensure Safe Use of Plant

- s(19)(3)f WHS Act – Duty to Provide Adequate Information, Training, Instruction and Supervision

- s(39) WHS Regulations – Duty to Provide Adequate Information, Training, and Instruction

- s(203) WHS Regulations – Management of Risks to Health and Safety (PCBUs with management or control of plant)

The Code of Practice “Managing risks of plant in the workplace” states that employers (PCBUs) must provide workers with information, training, and instruction as necessary to protect them from risks arising from the use of the plant.

FAQ

What is a brake press?

A brake press, also known as a press brake, is a machine tool used for bending sheet metal into various shapes and angles by applying force through a hydraulic or mechanical press.

What is a brake press used for?

It is commonly used in metalworking shops, manufacturing plants, and fabrication facilities for forming metal components used in various industries such as automotive, aerospace, and construction.

What hazards are involved in brake press use?

Some hazards that are involved in brake press use include:

- Crushing injuries

- Pinch points

- Flying debris

- Electric shock

What are some safety controls that can be utilised during brake press use?

Some safety controls that can be utilised include:

- Using machine guards and safety devices to prevent access to moving parts

- Providing proper training for operators on safe operating procedures

- Conducting regular maintenance checks to ensure equipment integrity

- Using appropriate personal protective equipment (PPE) such as safety goggles and gloves

Did you know?

Did you know that the history of bending metal for manufacturing purposes dates back thousands of years, but the modern press brake, as we know it, began development in the late 19th and early 20th centuries? The evolution of these machines, particularly with the advent of CNC technology, has dramatically transformed metal fabrication, enabling the creation of components with complex geometries that were difficult, if not impossible, to produce with earlier technology. Today, press brakes continue to be a cornerstone of metalworking and fabrication, embodying advances in automation, precision, and safety.

Article Sources and Further Reading

- Model Code of Practice: Managing risks of plant in the workplace (Safe Work Australia) <https://www.safeworkaustralia.gov.au/doc/model-code-practice-managing-risks-plant-workplace>

- Plant (Safe Work Australia) <https://www.safeworkaustralia.gov.au/safety-topic/managing-health-and-safety/plant>

- The Complete Guide to WHS Policies and Procedures in Australia (Spire Safety) <https://spiresafety.com.au/resources/guide-to-whs-policies-and-procedures/>

- What is a PCBU? (Spire Safety)<https://spiresafety.com.au/resources/what-is-a-pcbu/>