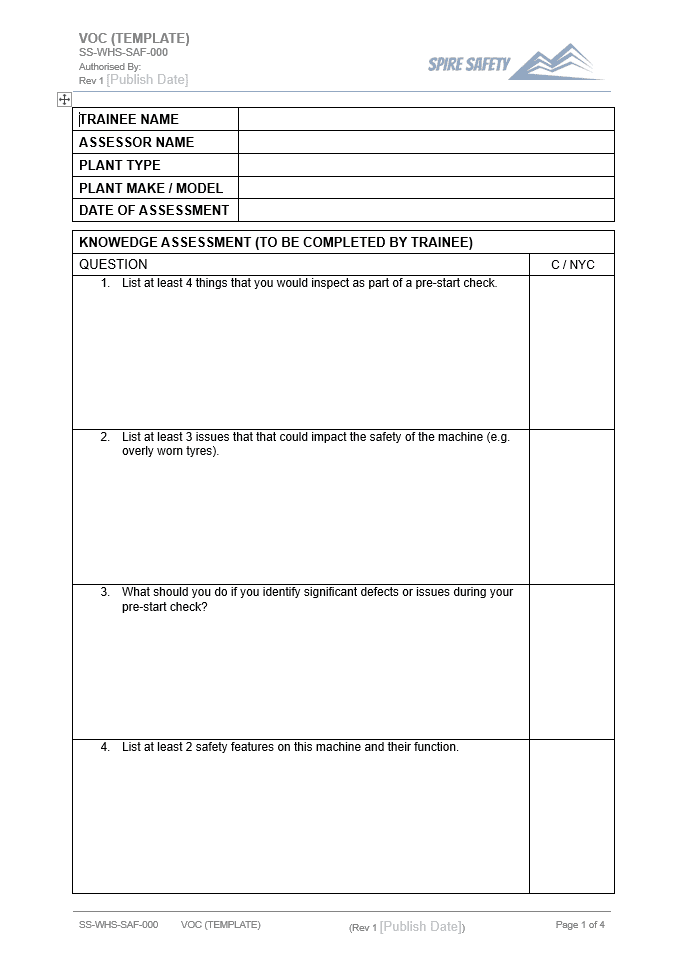

Free Nail Gun VOC (Verification of Competency) Template

Download our free Nail Gun VOC Template:

*For internal use only. Not for resale or redistribution. By downloading, you agree to our Free Resources Licensing Agreement.

Purpose of a Nail Gun VOC Document

Nail Gun VOCs are used to verify a worker’s competence in nail gun use. The primary goal is to protect workers from injury or illness through effective training and competency procedures. This form is broadly aligned with AS45001:2018.

How to Use

This Nail Gun VOC should be completed by a competent person in consultation with the trainee who will use the plant.

This document is a template only and it must be customised for your business. Other aspects that may need to be considered include, but are not limited to, ensuring that:

- Relevant legal requirements have been met,

- Workplace specific risks are identified and managed, and

- Workers are consulted with during the customisation / review process.

When to Use

Nail Gun VOCs should be completed prior to the worker operating plant or equipment within your business.

Who Should Use

Nail Gun VOCs must be completed by someone who is familiar with operation of the piece of plant or equipment. This person should also be competent in training and assessment methods.

Legal Considerations

There is no specific legal requirement to complete a documented Verification of Competency (VOC). However, it is best practice. Completing a thorough Verification of Competency can help meet general legal duties, including:

- s(19)(3)c WHS Act – Duty to Provide Safe Systems of Work

- s(19)(3)d WHS Act – Duty to Ensure Safe Use of Plant

- s(19)(3)f WHS Act – Duty to Provide Adequate Information, Training, Instruction and Supervision

- s(203) WHS Regulations – Management of Risks to Health and Safety (PCBUs with management or control of plant)

The Code of Practice “Managing risks of plant in the workplace” states that employers (PCBUs) must ensure workers are trained and have the appropriate skills to carry out a particular task safely.

FAQ

What is a nail gun?

A nail gun, also known as a nailer, is a power tool used for quickly and efficiently driving nails into various materials such as wood, plastic, and metal. It operates by compressing air, electromagnetism, or combustion to force a nail through the material with a high degree of precision and speed. Nail guns are commonly used in construction, woodworking, and framing projects, replacing traditional hammering methods to save time and effort. They come in different types, including pneumatic, electric, and cordless models, each suited to different applications and user preferences.

What is a nail gun used for?

A nail gun is primarily used for driving nails or fasteners into various materials such as wood, metal, or concrete quickly and efficiently. It eliminates the need for manual hammering and allows for rapid installation of nails in construction, carpentry, woodworking, and DIY projects. Nail guns come in different types, including pneumatic, electric, and cordless, each suited to different applications and user preferences. They are essential tools for tasks such as framing, roofing, flooring, and trim work, where precise and consistent fastening is required.

What hazards are involved in nail gun use?

Many hazards exist in nail gun operation, for example:

- Puncture Injuries

- Struck-By Accidents

- Electrocution

- Kickback

- Noise Exposure

- Jamming

- Eye Injuries

To mitigate these hazards, proper training, adherence to safety protocols, regular equipment maintenance, use of personal protective equipment (PPE), and thorough site inspections are essential.

Do you need training to operate a nail gun?

In general, the level of training provided to workers must take into consideration “the nature of the work, the nature of the risks and the control measures required” – WHS regulations s(39). That is, for plant that poses no or minimal risks, there may be very little training required. As the risks of the plant increases, the requirement for training also increases.

To demonstrate competence in nail gun operation, workers can complete the RTO unit https://training.gov.au/Training/Details/RIICRC319E.

Did You Know?

The first pneumatic nail gun, powered by compressed air, was invented in the 1930s by Morris Pynoos, a civil engineer. However, it wasn’t until the 1950s that the modern version of the nail gun, as we know it today, was introduced, featuring safety enhancements and improved efficiency. Today, nail guns are widely used in the construction industry, revolutionizing the speed and ease of fastening materials.

Article Sources and Further Reading

Model Code of Practice: Managing risks of plant in the workplace (Safe Work Australia) <https://www.safeworkaustralia.gov.au/doc/model-code-practice-managing-risks-plant-workplace>

Plant (Safe Work Australia) <https://www.safeworkaustralia.gov.au/safety-topic/managing-health-and-safety/plant>

What is a PCBU? (Spire Safety) <https://spiresafety.com.au/resources/what-is-a-pcbu/>