PPE Types and Uses in Australia: Safety Essentials

Have you ever wondered why certain workplaces strictly mandate the use of specific Personal Protective Equipment (PPE), even when other safety measures are in place?

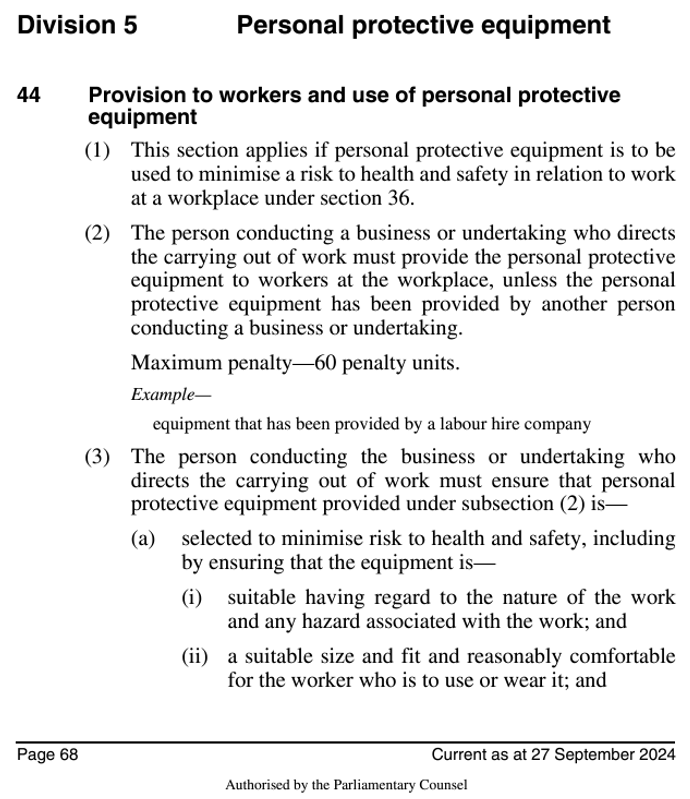

Personal protective equipment in Australia is not merely an option but a legal necessity, mandated by the Work Health and Safety Act 2011 (WHS Act).

In this article, we will explore some different types of PPE , some specific legal requirements and other obligations.

What is PPE?

The WHS Regulations defines PPE as “anything used or worn by a person to minimise risk to the person’s health and safety, including air supplied respiratory equipment.”

PPE includes items such as, but not limited to:

- Helmets / head protection,

- Safety glasses,

- Respirators,

- Gloves,

- Earmuffs,

- Safety shoes, and

- High-visibility clothing.

PPE Compliance in Australia

Industries are bound by the WHS Act 2011, mandating that employers provide adequate PPE free of cost to safeguard employees from occupational hazards. This legislation underscores that supplying PPE forms part of a PCBU’s duty of care.

As well as providing the equipment, employers must also provide workers with proper training including :

- When to use PPE,

- Wearing / fitting PPE,

- Storage, and

- Maintenance checks and procedures (cleanliness / hygienic / in good working order).

PPE Examples

Various types of PPE are utilised in Australian workplaces to safeguard employees from industry-specific risks. Below are some PPE examples and their specific uses.

Respirators:

Devices such as disposable and half-face respirators are essential when operating power tools that generate dust, mist, and fumes. Disposable respirators come in two main types – P1 and P2, providing protection against mechanically and thermally generated particles, while half-face respirators with suitable filters address the needs of environments with organic gases and solvents.

Safety Glasses:

Safety glasses are required in workplaces with risks of flying debris or exposure to hazardous substances.

Such equipment is designed to protect workers’ eyes from particles and chemical splashes.

Protective Clothing:

Protective clothing is essential in high-risk jobs where visibility and protection from environmental elements are required. This includes high-visibility clothing and UV protective gear, ensuring that workers are both seen and safe while on the job.

Hard Hats:

Hard hats are a standard requirement on construction sites for head protection. They offer impact cushioning and should be certified to AS 1801:1997 standards. Hard hats safeguard workers from falling objects and other head injury risks prevalent in construction and industrial environments.

Ear Protection:

It is a requirement that hearing protection be worn if noise levels rise above 85dBA (Managing Noise and Preventing Hearing Loss at Work Code of Practice). Options include earplugs, typically offering Class 3 protection, and earmuffs, which provide either Class 4 or Class 5 protection. Some earmuffs feature electronic noise cancellation, suitable for varying noise level reductions.

Harnesses:

Safety harnesses are vital for protecting workers in jobs that involve working at heights, such as tree lopping, construction, and roofing. They prevent falls and can help minimise the risk of serious injuries. Proper use of safety harnesses involves ensuring that they are correctly fitted and securely attached to anchor points.

Safety Gloves:

Safety gloves are designed to protect workers’ hands from various hazards such as:

- Cuts,

- Abrasions,

- Chemicals, and

- Heat.

Different types of gloves are available depending on the task, such as cut-resistant gloves for handling sharp objects, chemical-resistant gloves for working with hazardous substances, and insulated gloves for electrical work.

PPE Training

Training is a critical component of PPE compliance in the Australian workplace. Workers need to be proficient in:

- Knowing when PPE is required,

- How to fit applicable PPE,

- How to use PPE,

- How to clean and maintain PPE, and

- Appropriate storage of PPE.

Workers should also be trained to recognise the limitations of their PPE and understand that it does not eliminate hazards but reduces exposure to them.

They must also be familiar with reporting any issues with PPE, such as defects or discomfort, which can lead to improper protection.

Ongoing refresher training and practical demonstrations ensure that workers remain confident in using their PPE correctly and are up to date with the latest safety protocols and equipment advancements.

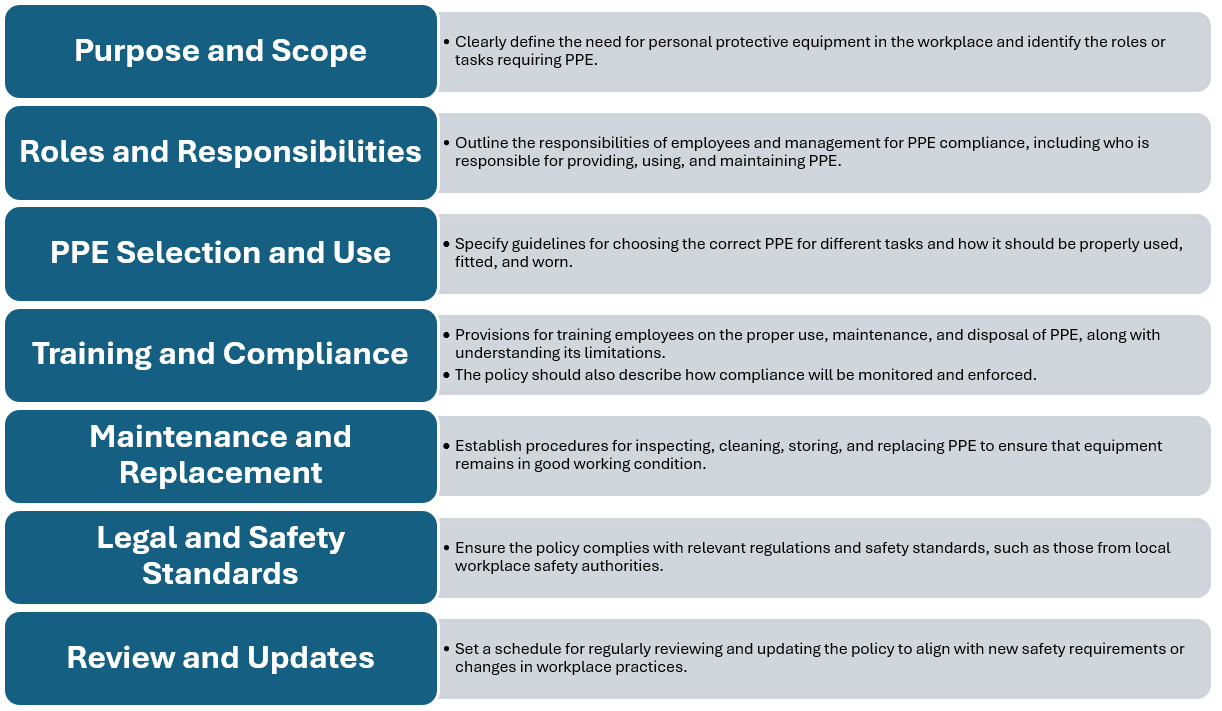

PPE Policies

A company PPE policy should include several elements to ensure the protection of workers from hazards:

By addressing the above points, a PPE policy can be developed that clearly defines employee responsibilities and supports a safe working environment.

FAQ

What are the common types of PPE?

Common types of PPE used in Australian workplaces include:

- Respirators,

- Safety glasses,

- Protective clothing,

- Hard hats,

- Safety gloves,

- Ear protection, and

- Fall protection harnesses.

Each type serves to protect workers from specific hazards associated with their job.

What is the importance of PPE compliance in Australia?

PPE compliance is crucial in Australia to ensure workplace safety and to adhere to national regulations. Employers are legally obligated to provide suitable and well-fitting PPE at no cost to their employees, ensuring it is properly maintained and used correctly.

How important is the correct fit of PPE?

Ill-fitting PPE can compromise protection and comfort, reducing its effectiveness in safeguarding against workplace hazards.

What are the best practices for maintaining and storing PPE?

Best practices for maintaining and storing PPE include:

- Regular inspections,

- Proper cleaning, and

- Following manufacturers’ guidelines for storage.

Additional reading and source links:

- Australian PPE Standards & Requirements: Complete Guide

- The Role of Personal Protective Equipment (PPE) in Safety » Locksafe

- What Is PPE? | Guide To Using PPE Gear | TTFS

- Personal protective equipment (PPE)

- Types of PPE for Power Tool Use

- Personal protective equipment (PPE) – WHS duties

- Personal protective equipment (PPE) Safety

- PPE | Safe Work Australia

- Personal Protective Equipment (PPE) For Flammable Liquids

- Protective items, equipment and products

- Respiratory protective equipment (RPE)

- Personal protective equipment