Crystalline Silica Regulations: The New Asbestos

Crystalline silica (silica) is found in many building products including sand, concrete, stone, and mortar. Read on to learn about the new crystalline silica regulations.

Common products and their crystalline silica content:

- Concrete: 25 – 75% crystalline silica

- Engineered stone (or manufactured stone): up to 95%

- Bricks: Up to 30%

- Mortar: 25 – 75%

- Cement sheeting: 10 – 30%

- Demolition dust: 3 – 4%

- Granite 20 – 45%

- Sandstone: 70 – 90%

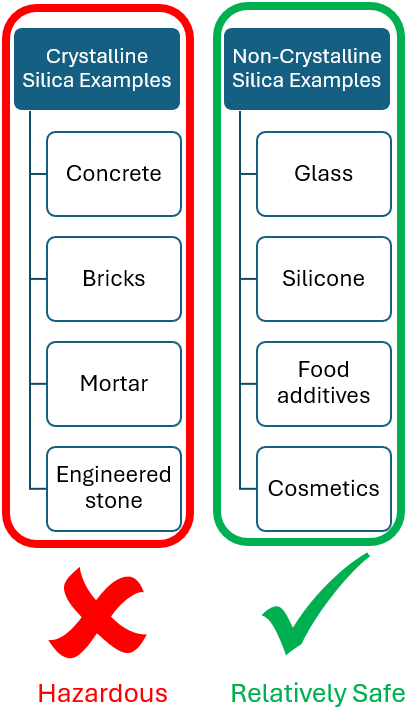

Silica vs Crystalline Silica

In terms of workplace safety, the primary concern is crystalline silica (with examples above). Regular (or non-crystalline silica) is present in materials like glass, silicon carbide, and silicone, which pose significantly lower risks to lung health.

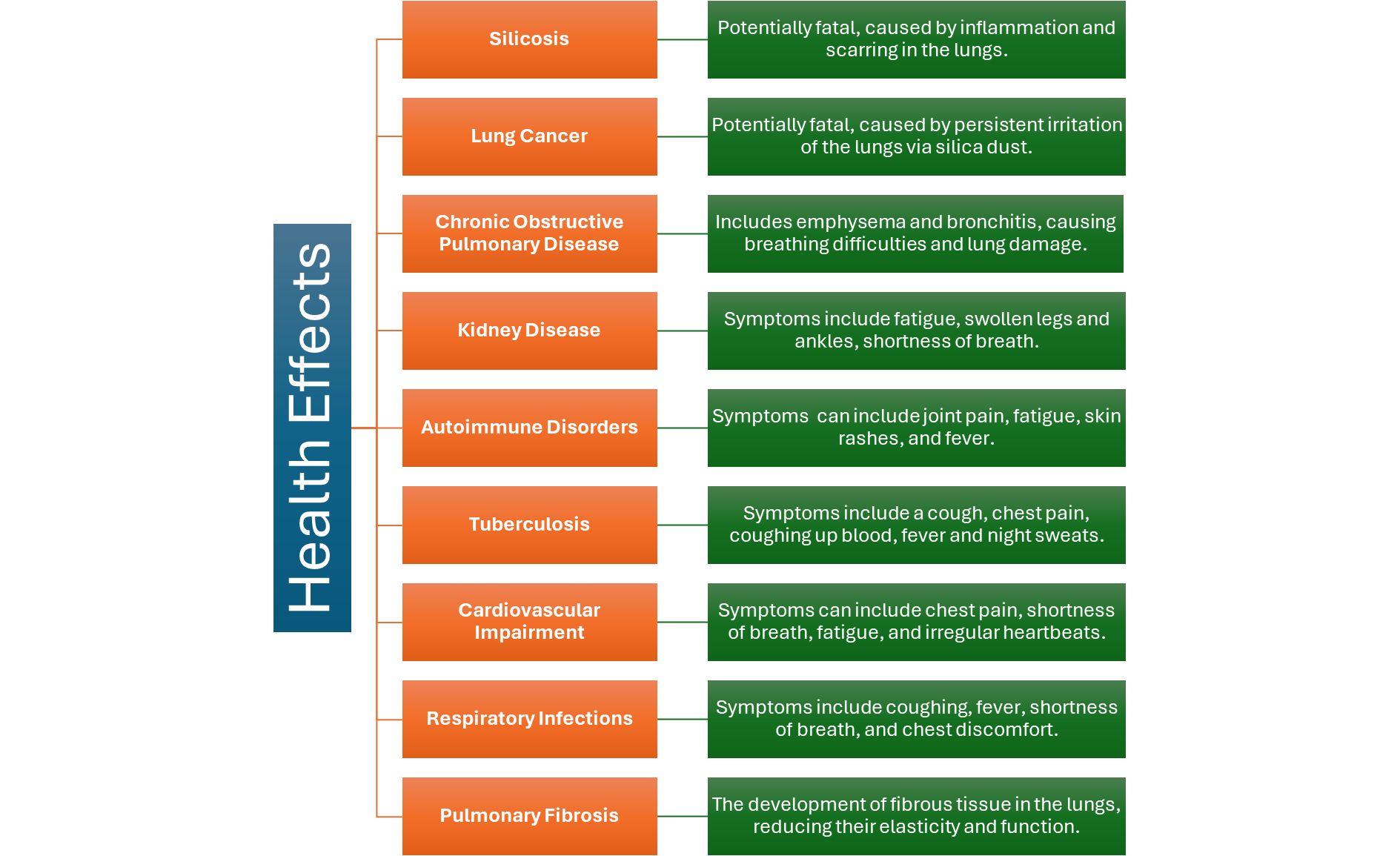

Health Effects of Crystalline Silica

Crystalline silica primarily effects the lungs and respiratory tract.

It can cause the following diseases, some of which are fatal or extremely debilitating.

- Silicosis – A potentially fatal lung disease caused by inflammation and scarring in the lungs.

- Lung Cancer – Potentially fatal cancer. Can be caused by persistent irritation of the lungs via silica dust.

- Chronic Obstructive Pulmonary Disease (COPD) – Includes conditions like emphysema and chronic bronchitis, causing breathing difficulties and irreversible lung damage.

- Kidney Disease – Symptoms can include fatigue, swelling in the legs and ankles, shortness of breath, and high blood pressure.

- Autoimmune Disorders – Symptoms vary depending on the specific disorder but can include joint pain, fatigue, skin rashes, and fever.

- Tuberculosis – Symptoms include a persistent cough, chest pain, coughing up blood, fever, night sweats, and weight loss.

- Cardiovascular Impairment – Symptoms can include chest pain, shortness of breath, fatigue, and irregular heartbeats.

- Respiratory Infections – Symptoms include coughing, fever, shortness of breath, and chest discomfort.

- Pulmonary Fibrosis – The development of fibrous tissue in the lungs, reducing their elasticity and function.

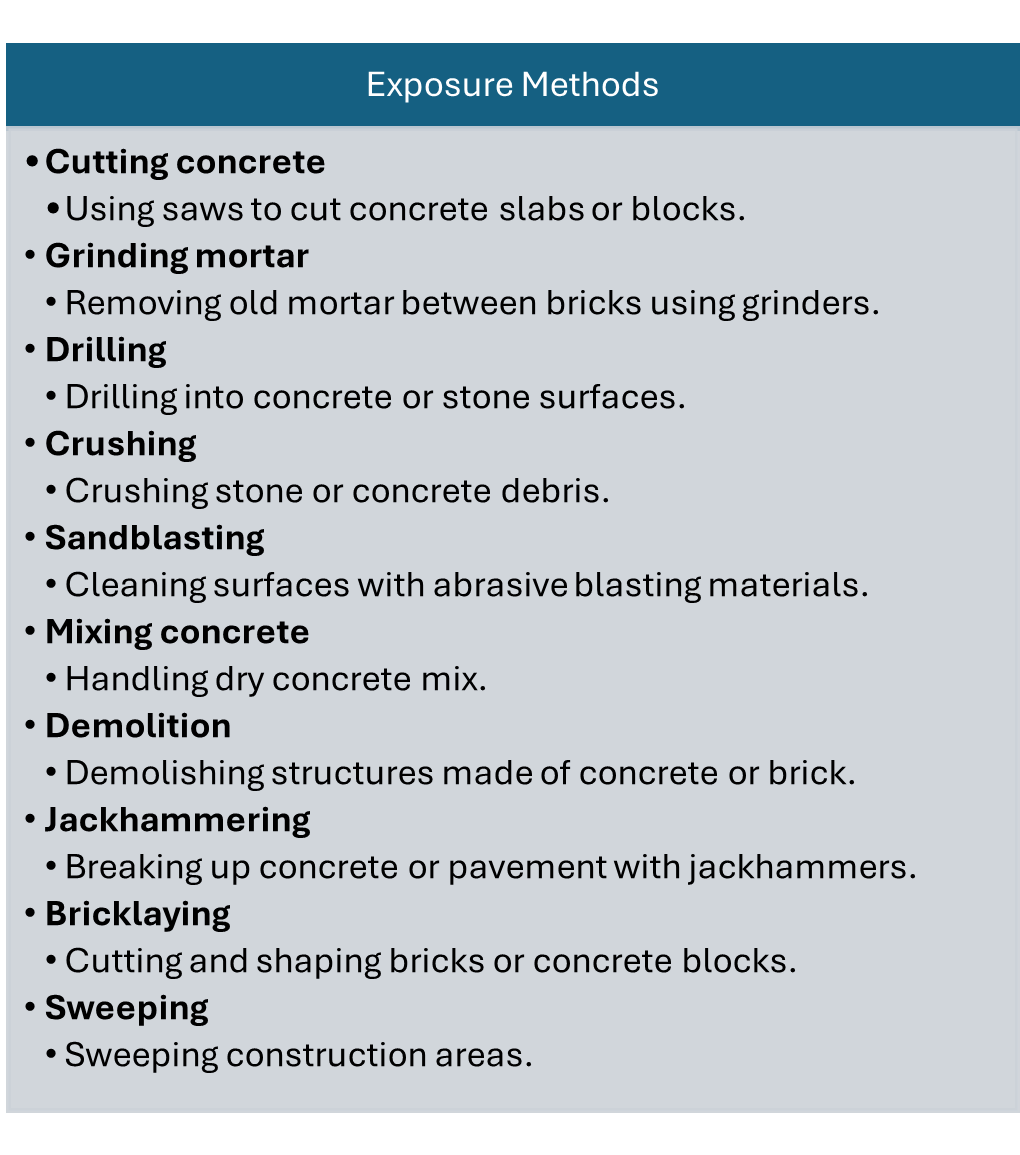

Silica Dust Exposure

When workers cut, crush, drill, polish or grind products containing silica, dust particles are produced which enter the lungs and respiratory tract. Some examples of activities that cause silica dust exposure include cutting, grinding drilling, crushing, jackhammering, demolition and sweeping.

Crystalline Silica Regulations

General Legal Duties

PCBUs (e.g. companies or business owners) have always been responsible for managing the risks of crystalline silica under the general requirements within WHS Act and Regulations, including the WHS Act s(19)(3):

- Subsection (a) Providing a safe work environment

- Subsection (c) Providing safe systems of work

- Subsection (d) Ensuring safe use of substances

- Subsection (g) Monitoring the health of workers and workplace conditions

Specific Legal Duties

More recently, crystalline silica has come under more stringent regulatory scrutiny. Likely due to the rise in silica related illnesses and fatalities. Thus, specific crystalline silica regulations have been published.

Crystalline Silica Regulations (Chapter 8A)

Safe Work Australia added a sub-chapter to the harmonized WHS regulations that addresses crystalline silica, or what it calls Crystalline Silica Substances (CSS). These new regulations state that the processing (e.g. drilling, grinding etc.) of CSS must be controlled, with controls including:

Eliminating or minimizing the risk of exposure, including via:

- the isolation of a person from dust exposure

- a fully enclosed operator cabin fitted with air filtration system

- wet dust suppression

- on-tool extraction system

- an effective local exhaust ventilation system

- respiratory protective equipment

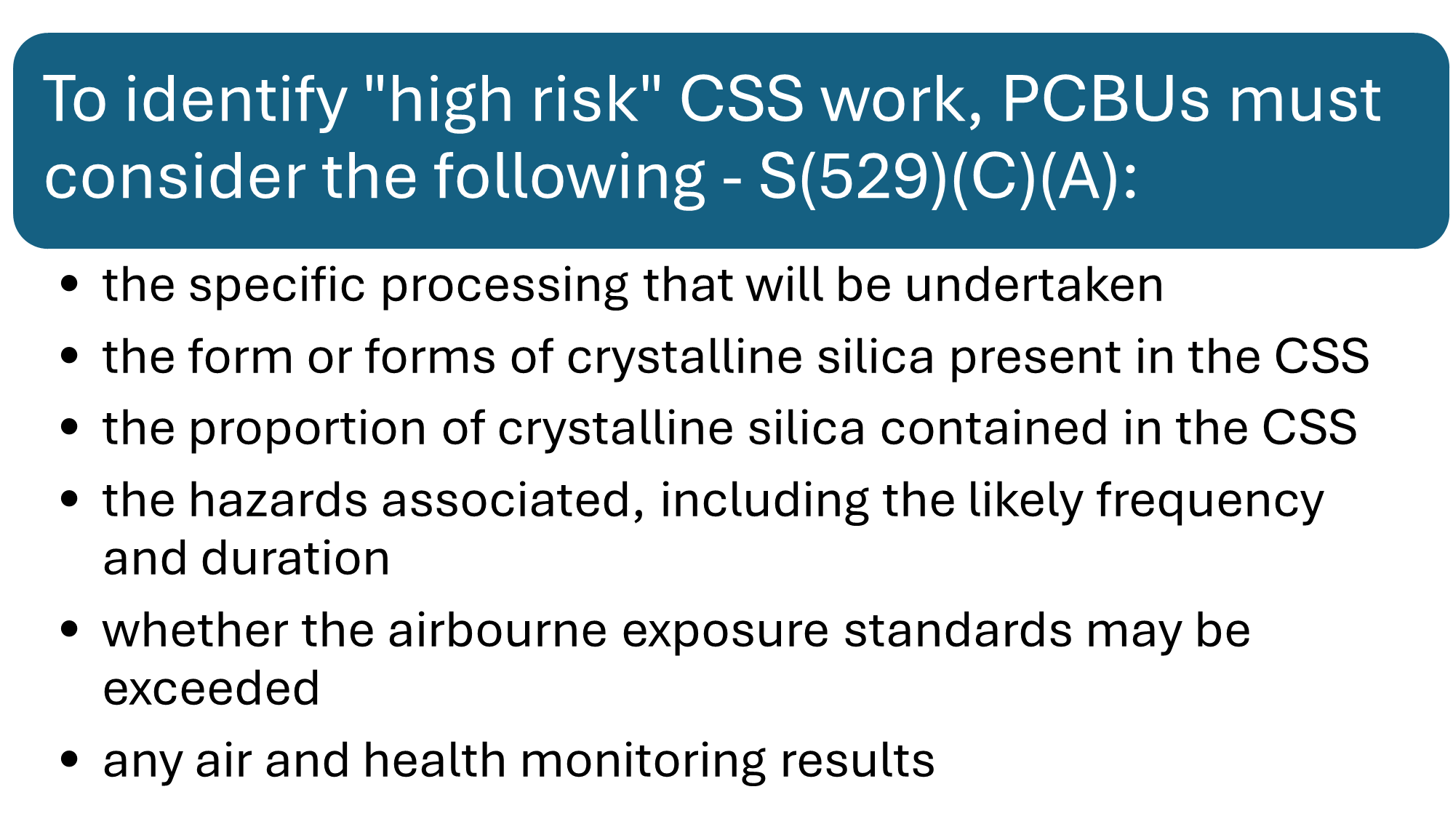

The regulations also require the PCBU to identify CSS work that is “high risk”.

If the work is identified as high risk, the PCBU must ensure:

- A silica risk control plan is developed and implemented

- Compliance with the control plan is enforced

- Workers are trained about the risk of silica

- Air monitoring is undertaken

A blanket ban on the manufacture, supply, processing or installing of engineered stone benchtops, panels and slabs is outlined within the harmonsed WHS regulations (Part 8A.2).

Crystalline Silica Codes of Practice

At the time of writing, there has been no crystalline silica code of practice published by Safe Work Australia. However, some states have implement their own codes of practice. For example:

To check whether state specific regulations exist in your jurisdiction, check with your local regulator:

- Safe Work Australia (Model WHS laws) <https://www.safeworkaustralia.gov.au/law-and-regulation/model-whs-laws>

- Comcare (Scheme and legislation – Comcare) <https://www.comcare.gov.au/scheme-legislation>

- QLD (Work health and safety laws) <https://www.worksafe.qld.gov.au/laws-and-compliance/work-health-and-safety-laws>

- NSW (Legislation – SafeWork NSW) <https://www.safework.nsw.gov.au/legal-obligations/legislation>

- ACT (Acts and regulations) <https://www.worksafe.act.gov.au/laws-and-compliance/acts-and-regulations>

- SA (Legislation) <https://www.safework.sa.gov.au/resources/legislation>

- WA (Work health and safety legislation) <https://www.commerce.wa.gov.au/worksafe/work-health-and-safety-legislation>

- NT (The legislative framework – NT WorkSafe) <https://worksafe.nt.gov.au/forms-and-resources/bulletins/the-legislative-framework>

- TAS (Acts and Regulations) <https://worksafe.tas.gov.au/topics/laws-and-compliance/acts-and-regulations>

- VIC (Occupational Health and Safety Act and regulations) <https://www.worksafe.vic.gov.au/occupational-health-and-safety-act-and-regulations>

Health Monitoring Crystalline Silica Regulations

As per WHS Regulations model, PCBUs must provide health monitoring for workers if they carry out ongoing work handling, generating, or storing crystalline silica. It applies in case of significant risk to the worker’s health due to exposure to silica.

The crystalline silica’s minimum health monitoring requirements are:

- Collection of medical, occupational, and demographic history.

- Personal exposure records.

- Questionnaire on standardised respiratory.

- Standardised respiratory function tests, for example – FEV1, FVC and FEV1/FVC, and

- Chest X-Ray full PA view (baseline and high-risk workers only).

FAQs

What is crystalline silica?

Crystalline silica is a common mineral found in materials like sand, stone, concrete, and mortar.

How can exposure to crystalline silica affect workers’ health?

It can cause serious diseases such as silicosis, lung cancer, COPD, and kidney disease.

Who is at risk from exposure to crystalline silica?

Workers in construction, mining, and manufacturing industries are at higher risk.

What are the symptoms of silicosis?

Symptoms include persistent cough, shortness of breath, fatigue, and chest pain.

How does silica dust exposure occur in the workplace?

Exposure occurs during activities like cutting, grinding, drilling, or crushing materials containing silica.

How can silica exposure be controlled?

Use engineering controls, such as water sprays and ventilation, and provide personal protective equipment (PPE).

Why can’t workers just wear respirators?

Respirators are a last resort; engineering controls and work practices are more effective and sustainable.

What is the permissible exposure limit (PEL) for crystalline silica?

The PEL is the maximum amount of silica dust a worker can be exposed to, set by regulatory agencies like OSHA.

What is the purpose of health monitoring?

To monitor workers’ health and detect early signs of silica-related diseases.

Did You Know?

The health risks associated with crystalline silica have been known for centuries. In 1700, Dr. Bernardino Ramazzini, often called the father of occupational medicine, identified evidence of silicosis in stone cutters. This early recognition of the dangers of silica dust laid the groundwork for future occupational health and safety measures.

Articles and Further Reading

- A Short History of Silica and Asbestos (Spire Safety) <https://spiresafety.com.au/resources/a-short-history-of-silica-and-asbestos/>

- What is a PCBU? (Spire Safety) <https://spiresafety.com.au/resources/what-is-a-pcbu/>

- Crystalline silica and silicosis (Safe Work Australia) <https://www.safeworkaustralia.gov.au/safety-topic/hazards/crystalline-silica-and-silicosis>

- Crystalline silica – general fact sheet (SafeWork NSW) <https://www.safework.nsw.gov.au/resource-library/hazardous-chemicals/crystalline-silica/crystalline-silica-general-fact-sheet#:~:text=What%20is%20crystalline%20silica%3F,on%20national%20and%20international%20sources.>