FREE Cotton Picker SOP (Safe Operating Procedure) Template

Download our free Cotton Picker SOP Template:

*For internal use only. Not for resale or redistribution. By downloading, you agree to our Free Resources Licensing Agreement.

Purpose of a Cotton Picker SOP

Purpose of a Cotton Picker SOP

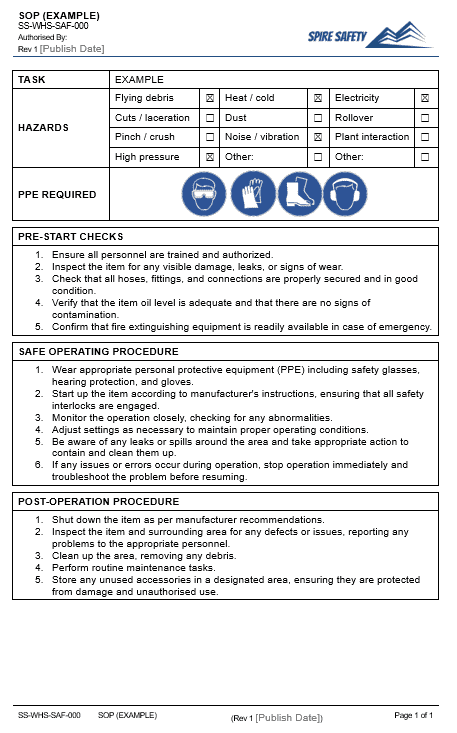

Cotton picker SOPs outline a safe operating procedure for cotton picker use. Cotton picker SOPs can also be used as a training and induction document. The primary goal is to protect workers from injury or illness by outlining a safe system of work and providing adequate training and instruction. This form is broadly aligned with AS45001:2018.

How to Use

Cotton picker SOPs should be communicated to workers before they complete the task. A hard copy can also be displayed in the workplace or provided at the workface. You can also use cotton picker SOPs during the induction or onboarding process.

NOTE: This document is a template only and it must be customised for your business. Other aspects that need to be considered include, but are not limited to, ensuring that:

- Relevant legal requirements have been met,

- Workplace specific risks are identified and managed, and

- Workers are consulted with during the customisation / review process.

When to Use

Workers should read and agree to comply with cotton picker SOPs prior to operation within your business. They can also be used for refresher training periodically.

Who Should Use

Cotton picker SOPs should be developed by a competent person. The SOP is then read and followed by the worker completing the task. New workers should also read and understand the SOPs during the induction or onboarding process.

Legal Considerations

There is no specific legal requirement to have a documented Safe Operating Procedure (SOP). However, it is best practice, as having SOPs can assist in meeting general legal duties, including:

- s(19)(3)c WHS Act – Duty to Provide Safe Systems of Work

- s(19)(3)d WHS Act – Duty to Ensure Safe Use of Plant

- s(19)(3)f WHS Act – Duty to Provide Adequate Information, Training, Instruction and Supervision

- s(39) WHS Regulations – Duty to Provide Adequate Information, Training and Instruction

- s(203) WHS Regulations – Management of Risks to Health and Safety (PCBUs with management or control of plant)

The Code of Practice “Managing risks of plant in the workplace” states that employers (PCBUs) must provide workers with information, training, and instruction as necessary to protect them from risks arising from the use of the plant.

FAQ’s

What is a cotton picker?

A cotton picker is a specialised machine used on cotton farms to automate the process of harvesting cotton bolls from the plant.

What is a cotton picker used for?

Cotton pickers are designed for efficiently collecting ripe cotton fibres from the boll while leaving the plant structure largely intact.

What hazards are involved in cotton picker use?

Some hazards that are involved in cotton picker use include:

- Entanglement

- Falls

- Cuts/lacerations

- Noise

- Collisions

What are some safety controls that can be utilised during cotton picker use?

Some safety controls that can be utilised include:

- Guarding mechanisms

- Fall prevention

- PPE requirement

- Regular maintenance

- Operator training

Did you know?

Some advanced cotton pickers are equipped with onboard module builders, which immediately process and compact the picked cotton into large round or rectangular modules ready for ginning, streamlining the entire harvest chain.

Article Sources and Further Reading

- Model Code of Practice: Managing risks of plant in the workplace (Safe Work Australia) <https://www.safeworkaustralia.gov.au/doc/model-code-practice-managing-risks-plant-workplace>

- Plant (Safe Work Australia) <https://www.safeworkaustralia.gov.au/safety-topic/managing-health-and-safety/plant>

- The Complete Guide to WHS Policies and Procedures in Australia (Spire Safety) <https://spiresafety.com.au/resources/guide-to-whs-policies-and-procedures/>

- What is a PCBU? (Spire Safety) <https://spiresafety.com.au/resources/what-is-a-pcbu/>

Purpose of a Cotton Picker SOP

Purpose of a Cotton Picker SOP