Free Rattle Gun SWMS (Safe Work Method Statement) Template

Download our free Rattle Gun SWMS:

*For internal use only. Not for resale or redistribution. By downloading, you agree to our Free Resources Licensing Agreement.

Read our Comprehensive Guide on Safe Work Method Statements.

Purpose of a Rattle Gun SWMS

Purpose of a Rattle Gun SWMS

A Rattle Gun SWMS is a document that identifies hazards and controls associated with rattle gun use. SWMS also list how the control measures will be implemented, monitored, and reviewed.

How to Use a Rattle Gun SWMS

This Rattle Gun SWMS is a template only and must be customised for your business by a competent person in consultation with workers.

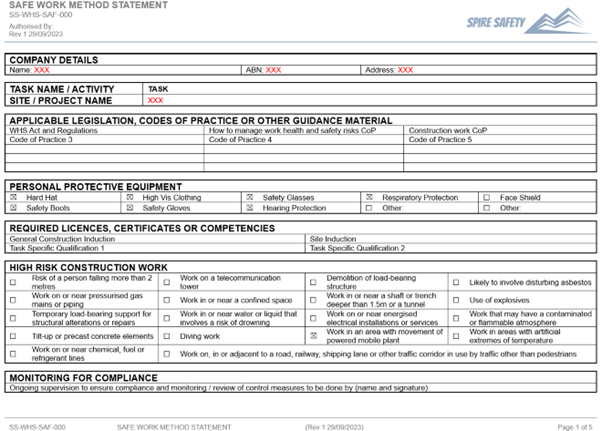

To complete the SWMS, fill in the details on the front page, including:

- Company details,

- Task, site and PPE details,

- Any relevant codes of practice, licences and high risk construction work, and

- Person responsible for monitoring and ensuring compliance.

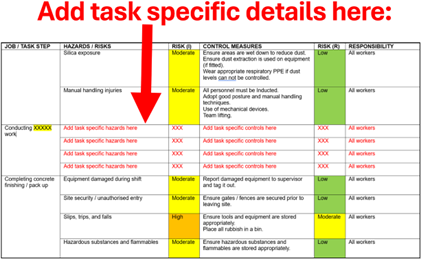

Ensure task-specific hazards and controls are added:

Other factors that need to be considered include, but are not limited to, ensuring that:

Other factors that need to be considered include, but are not limited to, ensuring that:

- Relevant legal requirements have been met,

- Workplace specific risks are identified and managed, and

- Workers are consulted with during the customisation / review process.

When to Use

Workers should read and agree to comply with the Rattle Gun SWMS prior to operation within your business. It can also be used for refresher training and during the induction / onboarding process.

Who Should Use

Rattle Gun SWMS should be developed by a competent person, in consultation with workers. The SWMS is then read and followed by the workers. New workers should also read and understand all applicable site / company SWMS during the induction or onboarding process.

Legal Considerations

Legally, businesses (or PCBUs) need to ensure a Safe Work Method Statement is completed prior to high-risk construction work commencing. The requirement for SWMS is outlined in:

- s(299) WHS Regulations – Safe Work Method Statements,

- s(300) WHS Regulations – Compliance with Safe Work Method Statements,

- s(301) WHS Regulations – SWMS Collection by Principal Contractor,

- s(302) WHS Regulations – Review of SWMS, and

- s(303) WHS Regulations – SWMS Record Keeping.

A SWMS may also help to meet:

- s(19)(3)c WHS Act – Duty to Provide Safe Systems of Work.

Depending on the task being completed, the following legal requirements may apply:

- s(44 – 47) WHS Regulations – Personal Protective Equipment,

- s(49 – 50) WHS Regulations – Managing Risks from Airbourne Contaminants,

- s(51 – 52) WHS Regulations – Hazardous Atmospheres,

- s(54 – 55) WHS Regulations – Falling Objects,

- s(56 – 59) WHS Regulations – Noise,

- s(60 – 61) WHS Regulations – Hazardous Manual Tasks,

- s(62 – 77) WHS Regulations – Confined Spaces,

- s(78 – 80) WHS Regulations – Falls,

- s(81) WHS Regulations – High Risk Work (Licencing),

- Part 4.6 WHS Regulations – Demolition Work,

- Part 4.7 WHS Regulations – General Electrical Safety,

- Part 4.9 WHS Regulations – Crystalline Silica,

- Chapter 5 WHS Regulations – Plant and Structures,

- Chapter 6 WHS Regulations – Construction Work,

- Chapter 7 WHS Regulations – Hazardous Chemicals, and

- Chapter 8 WHS Regulations – Asbestos.

FAQ’s

What is High Risk Construction Work?

High risk construction work is defined in WHS Regulations s(291). Some common types of high risk construction work are:

- Working at heights over 2m,

- Working in a trench or excavation over 1.5m,

- Work with mobile plant,

- Work on or adjacent to a roadway, and

- Work in confined spaces.

For a full list of high risk construction work, read our article 18 High Risk Construction Work Activities.

What is a Rattle Gun?

A rattle gun, also known as an impact wrench or impact gun, is a powerful pneumatic or electric tool used primarily for loosening and tightening nuts and bolts quickly and efficiently. It delivers high torque in short bursts, known as impacts, to achieve fast rotation and overcome resistance.

What Hazards Are Involved in Rattle Gun Use?

Some hazards that are involved in rattle gun use include:

- Noise,

- Cuts and lacerations,

- Risk of projectiles, and

- Pinching and crushing.

How Often Does a Rattle Gun SWMS Need to be Reviewed?

SWMS should be reviewed to ensure safety controls remain effective after:

- The task or environment changes,

- New processes or systems are incorporated into the task, and/or

- Following incidents or safety alerts.

If the task or environmental conditions do not change, SWMS should be reviewed informally by workers prior to each job with a “formal” (documented) review at least yearly.

Did You Know?

Rattle guns were originally developed for use in shipbuilding during World War I to rapidly assemble and disassemble large equipment and structures. Their ability to deliver high torque in short bursts revolutionised industrial assembly processes, significantly reducing labour time and enhancing productivity in manufacturing and maintenance sectors worldwide.

Article Sources and Further Reading

- A Comprehensive Guide to Safe Work Method Statements (Spire Safety) <https://spiresafety.com.au/resources/safe-work-method-statements/>

- The Complete Guide to WHS Policies and Procedures in Australia (Spire Safety) <https://spiresafety.com.au/resources/guide-to-whs-policies-and-procedures/>

- Safe Work Method Statement for High Risk Construction Work (Safe Work Australia) https://www.safeworkaustralia.gov.au/system/files/documents/1703/information-sheet-safe-work-method-statement.pdf

Purpose of a Rattle Gun SWMS

Purpose of a Rattle Gun SWMS