Principal Mining Hazard Management Plans: A Guide

Many states have implemented safety regulations requiring mining companies (including quarry operators) to implement mining safety management systems.

A mining safety management system will have many components, including inductions and safety inspections. Principal Mining Hazard Management Plans are a key component of these systems.

What is a Principal Mining Hazard?

A Principal Mining Hazard is a hazard that has the potential to cause serious injury or death/s.

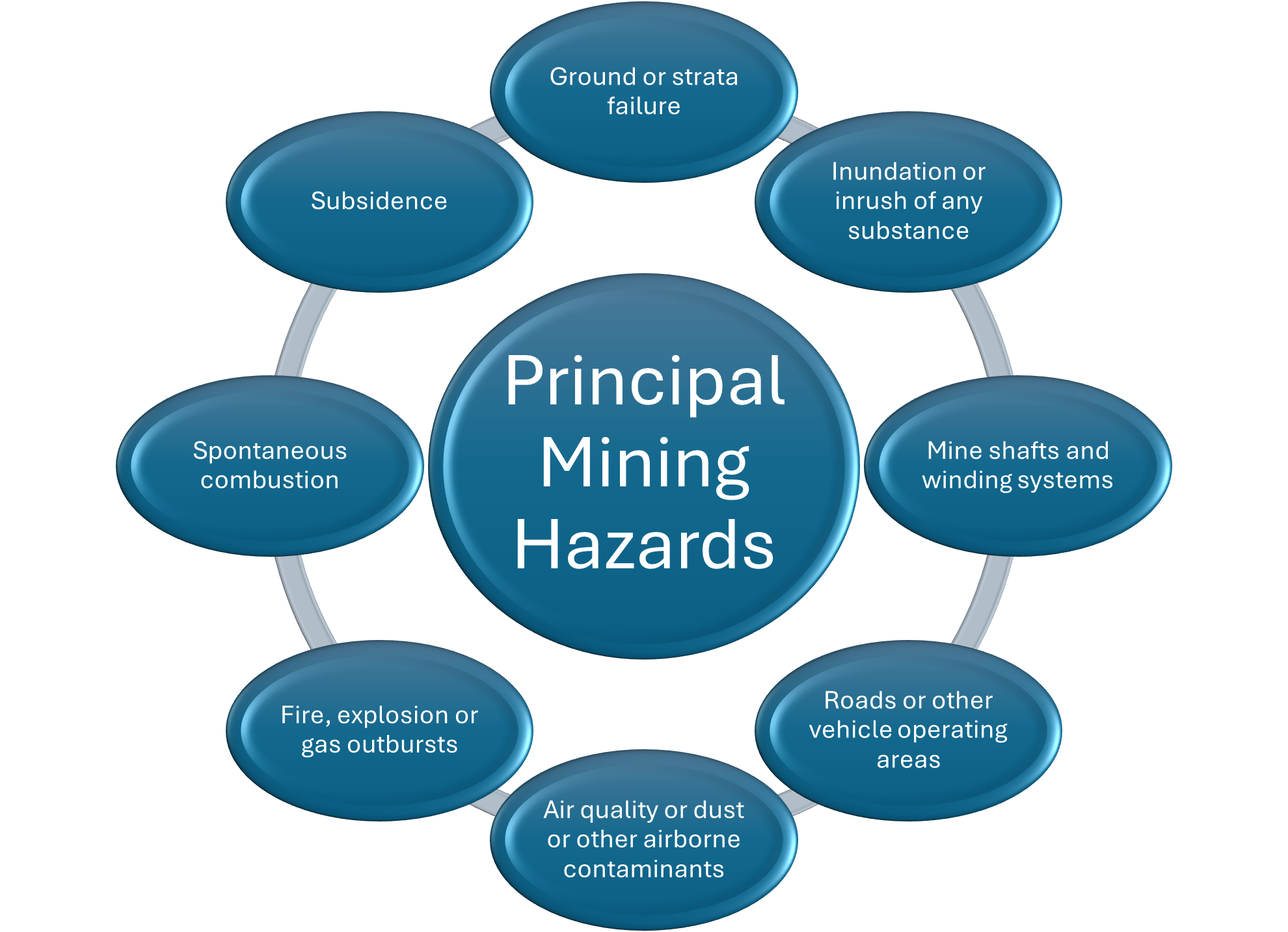

Principal Mining Hazards include (terminology varies interstate):

Principal Mining Hazards include (terminology varies interstate):

- Ground or strata failure: E.g. A collapse of the mine roof or walls could crush workers.

- Inundation or inrush of any substance: E.g. Sudden flooding from water or mud could drown miners.

- Mine shafts and winding systems: E.g. A malfunction or breakage in the hoisting system could cause a fall from height.

- Roads or other vehicle operating areas: E.g. A collision between vehicles or with pedestrians could result in fatal injuries.

- Air quality or dust or other airborne contaminants: E.g. Exposure to toxic gases or dust could lead to respiratory failure.

- Fire, explosion or gas outbursts: E.g. An explosion from gas buildup could cause burns or blast injuries.

- Spontaneous combustion: E.g. Uncontrolled fires from spontaneous combustion could lead to suffocation or burns.

- Subsidence: E.g. The sinking or collapse of the ground surface could trap or crush workers.

What are Principal Mining Hazard Management Plans (PMHMP)?

A Principal Mining Hazard Management Plan is a document which outlines how the principal mining hazard will be managed. The plans outline specific measures and procedures to mitigate risks associated with these hazards, ensuring the safety of workers. In general, the PMHMP must:

- identify and describe the hazard at the mine or petroleum operation

- assess the risks of health and safety to workers from the hazard

- describe the control measures required to manage the risks associated with the hazard

What Should a PMHMP Include?

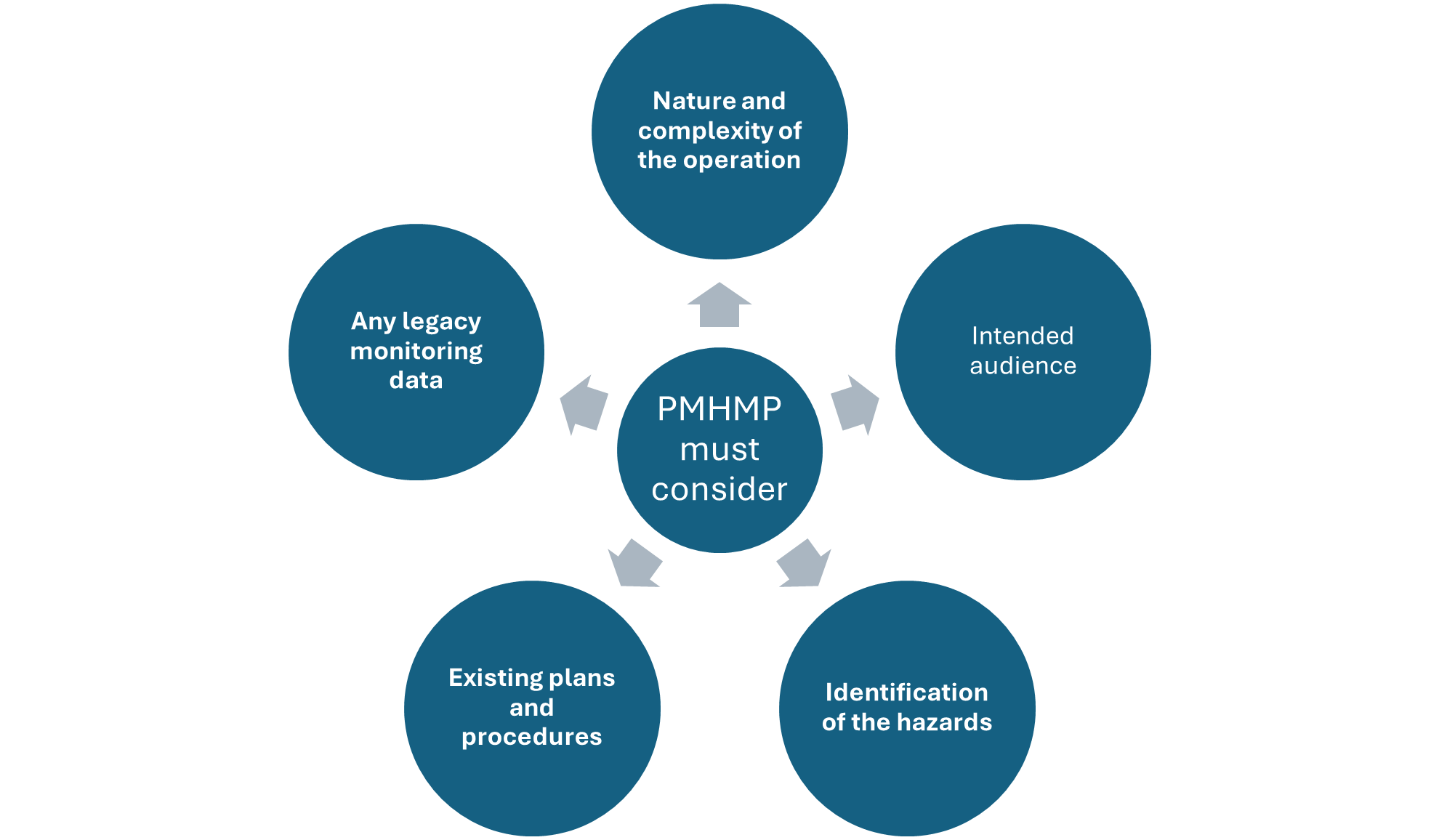

Safe Work NSW has published a guide for Preparing a principal hazard management plan. You should check with jurisdictions regulator for their guidance material.  Firstly, when developing a PMHMP, the mine (or quarry) operator must consider all relevant information, including:

Firstly, when developing a PMHMP, the mine (or quarry) operator must consider all relevant information, including:

- Nature and complexity of the operation: E.g. A highly complex operation may require more detailed and specific monitoring protocols.

- Intended audience: E.g. The plan should be written in clear, non-technical language if the audience includes non-specialists.

- Identification of the hazards: E.g. Identifying chemical hazards early can lead to the inclusion of specific safety measures.

- Existing plans and procedures or generic documentation: E.g. Leveraging existing emergency response plans can streamline the development process.

- Any legacy monitoring data: E.g. Historical data on pollutant levels can help set baseline measurements for new monitoring efforts.

The PMHMP should include information on how the principal mining hazard is managed. For example a Ground or Strata Failure PMHMP may include the following.

- Geotechnical Context

- Expected Formations

- Structural Characteristics and Hazards

- Controls for Ground or Strata Failure:

- Safe Design of Benches, Batters and Faces

- Exclusion Zones, Catch Bunds and Other Controls

- Monitoring Slope Instability and Other Hazards

A Roads and Other Vehicle Operating Areas PMHMP may include the following:

- Site Design and Planning:

- Site Access, Security and Parking Areas

- Haul Routes and Plant Operating Areas

- Banks and Steep Drops

- Exclusion Zones and Pedestrian Safety

- Offices / Amenity Areas

- Signage

- Road Standards

- Vehicle and Operator Safety:

- Safety of Vehicles

- Competence and Fitness of Operators

Training & Review of Principal Mining Hazard Management Plans

The Principal Mining Hazard Management Plan must be site specific and tailored to the unique operations of the mine / quarry. Ensuring staff are aware of and trained in the PMHMPs is also vital – refresher training may also be required. The PMHMP should be reviewed periodically, and workers should be consulted with during development and review of the plan.

FAQs

Do All Mines Need a Principal Mining Hazard Management Plan?

You will need to check with your state mines (or WHS) regulator to check whether your mine or quarry requires Principal Mining Hazard Management Plans.

Why is a PMHMP important?

PMHMPs are crucial for identifying, assessing, and controlling major hazards in mining operations, thereby reducing the risk of accidents and ensuring compliance with regulatory requirements.

What are the key components of a PMHMP?

Key components typically include hazard identification, risk assessment, control measures, emergency response procedures, and monitoring and review processes.

Who is responsible for developing a PMHMP?

The responsibility usually lies with the mine operator, often with input from safety professionals, engineers, and other relevant stakeholders.

How often should a PMHMP be reviewed and updated?

A PMHMP should be reviewed and updated at least yearly. It should also be reviewed when there are significant changes in operations, new hazards are identified, or after an incident occurs.

How can workers contribute to the development of a PMHMP?

Workers can provide valuable insights through their firsthand experience, participate in risk assessments, and offer feedback on proposed control measures.

Did You Know?

The tragic explosion at the Moura No. 2 underground coal mine in Queensland on August 7, 1994, which claimed the lives of 11 miners, was a pivotal moment in Australian mining safety. This disaster led to significant reforms in the late 1990s and early 2000s, drastically improving safety protocols across the industry. By 2003, the fatality rate had dropped to 12.4 per 100,000 workers, and a decade later, it was down to 3.4. These changes have made Australian mines much safer, although continuous efforts are needed to maintain and enhance safety standards.

Articles and Further Reading

- Mine Safety Management System Australia (Spire Safety) <https://spiresafety.com.au/mine-safety-management-system-australia/>

- Guide – Preparing a principal hazard management plan (Safe Work NSW) <https://www.resourcesregulator.nsw.gov.au/sites/default/files/2022-09/guide-preparing-a-principal-hazard-management-plan.pdf>

- Mining (Safe Work Australia) <https://www.safeworkaustralia.gov.au/safety-topic/industry-and-business/mining>