FREE Soldering Iron SOP (Safe Operating Procedure) Template

Download our free Soldering Iron SOP Template:

*For internal use only. Not for resale or redistribution. By downloading, you agree to our Free Resources Licensing Agreement.

Purpose of a Soldering Iron SOP

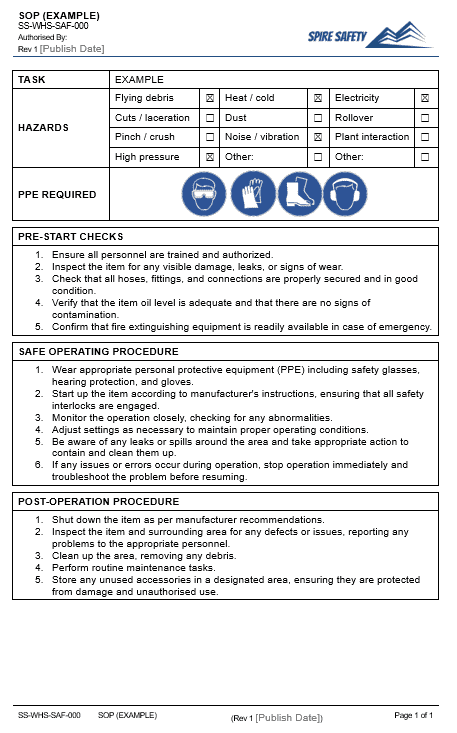

Soldering iron SOPs outline a safe operating procedure for soldering iron use. Soldering iron SOPs can also be used as a training and induction document. The primary goal is to protect workers from injury or illness by outlining a safe system of work and providing adequate training and instruction. This form is broadly aligned with AS45001:2018.

How to Use

Soldering iron SOPs should be communicated to workers before they complete the task. A hard copy can also be displayed in the workplace or provided at the workface. You can also use soldering iron SOPs during the induction or onboarding process.

NOTE: This document is a template only and it must be customised for your business. Other aspects that need to be considered include, but are not limited to, ensuring that:

- Relevant legal requirements have been met,

- Workplace specific risks are identified and managed, and

- Workers are consulted with during the customisation / review process.

When to Use

Workers should read and agree to comply with soldering iron SOPs prior to operation within your business. They can also be used for refresher training periodically.

Who Should Use

Soldering iron SOPs should be developed by a competent person. The SOP is then read and followed by the worker completing the task. New workers should also read and understand the SOPs during the induction or onboarding process.

Legal Considerations

There is no specific legal requirement to have a documented Safe Operating Procedure (SOP). However, it is best practice, as having SOPs can assist in meeting general legal duties, including:

- s(19)(3)c WHS Act – Duty to Provide Safe Systems of Work

- s(19)(3)d WHS Act – Duty to Ensure Safe Use of Plant

- s(19)(3)f WHS Act – Duty to Provide Adequate Information, Training, Instruction and Supervision

- s(39) WHS Regulations – Duty to Provide Adequate Information, Training, and Instruction

- s(203) WHS Regulations – Management of Risks to Health and Safety (PCBUs with management or control of plant)

The Code of Practice “Managing risks of plant in the workplace” states that employers (PCBUs) must provide workers with information, training, and instruction as necessary to protect them from risks arising from the use of the plant.

FAQ’s

What is a soldering iron?

A soldering iron is a hand tool used in the soldering process to join various types of metals together by melting solder around the joint. Solder is a metal alloy typically made of tin and lead (though lead-free solders are now predominantly used due to health and environmental concerns), which, when melted, forms a bond between metal workpieces.

What is a soldering iron used for?

Soldering irons are widely used in electronics to attach components to circuit boards or wires, in plumbing to seal copper piping, and in arts and crafts for jewelry and stained glass.

What hazards are involved in soldering iron use?

Some hazards that are involved in soldering iron use include:

- Fume inhalation.

- Splattering debris.

- Electrical shock.

- Burns

What are some safety controls that can be utilised during soldering iron use?

Some safety controls that can be utilised include:

- Using a heat-resistant stand when it’s not being used.

- Wearing PPE.

- Using fume extraction or work in a well-ventilated area.

- Using the appropriate grip.

- Reaching the required temperature before using.

- Ensuring correct solder type.

- Disconnecting or switching off the iron when not in use.

- Allowing cool down time before handling or storing.

Did you know?

The process of soldering has been practiced for thousands of years, with evidence of soldered items dating back to Mesopotamia and Ancient Egypt. Modern soldering irons, some small enough to be powered by a USB connection for use with electronic gadgets, are a far cry from the large, unwieldy copper bits that would be heated in a fire and hammered to a tip to be used for soldering metal items such as jewelry and cookware. With advances in technology, soldering irons are now available with precise temperature controls that make them suitable for a wide range of tasks, from delicate electronic circuitry to heavy-duty metalwork.

Article Sources and Further Reading

- Model Code of Practice: Managing risks of plant in the workplace (Safe Work Australia) <https://www.safeworkaustralia.gov.au/doc/model-code-practice-managing-risks-plant-workplace>

- Plant (Safe Work Australia) <https://www.safeworkaustralia.gov.au/safety-topic/managing-health-and-safety/plant>

- The Complete Guide to WHS Policies and Procedures in Australia (Spire Safety) <https://spiresafety.com.au/resources/guide-to-whs-policies-and-procedures/>

- What is a PCBU? (Spire Safety) <https://spiresafety.com.au/resources/what-is-a-pcbu/>