FREE Scraper SOP (Safe Operating Procedure) Template

Download our free Scraper SOP Template:

*For internal use only. Not for resale or redistribution. By downloading, you agree to our Free Resources Licensing Agreement.

Purpose of a Scraper SOP

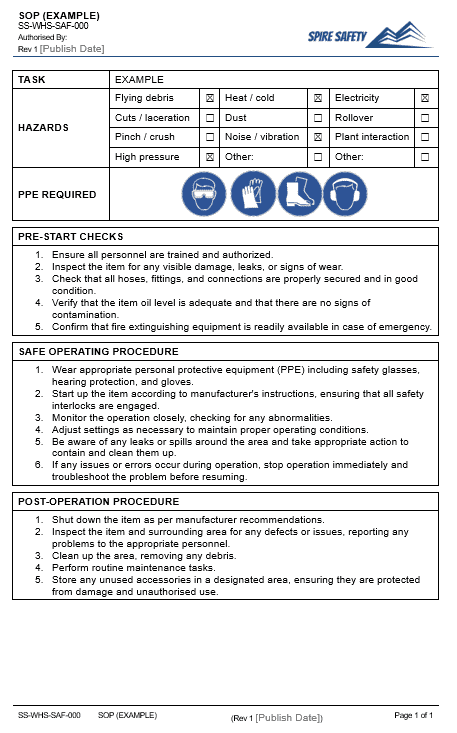

Scraper SOPs outline a safe operating procedure for scraper use. Scraper SOPs can also be used as a training and induction document. The primary goal is to protect workers from injury or illness by outlining a safe system of work and providing adequate training and instruction. This form is broadly aligned with AS45001:2018.

How to Use

Scraper SOPs should be communicated to workers before they complete the task. A hard copy can also be displayed in the workplace or provided at the workface. You can also use scraper SOPs during the induction or onboarding process.

NOTE: This document is a template only and it must be customised for your business. Other aspects that need to be considered include, but are not limited to, ensuring that:

- Relevant legal requirements have been met,

- Workplace specific risks are identified and managed, and

- Workers are consulted with during the customisation / review process.

When to Use

Workers should read and agree to comply with scraper SOPs prior to operation within your business. They can also be used for refresher training periodically.

Who Should Use

Scraper SOPs should be developed by a competent person. The SOP is then read and followed by the worker completing the task. New workers should also read and understand the SOPs during the induction or onboarding process.

Legal Considerations

There is no specific legal requirement to have a documented Safe Operating Procedure (SOP). However, it is best practice, as having SOPs can assist in meeting general legal duties, including:

- s(19)(3)c WHS Act – Duty to Provide Safe Systems of Work

- s(19)(3)d WHS Act – Duty to Ensure Safe Use of Plant

- s(19)(3)f WHS Act – Duty to Provide Adequate Information, Training, Instruction and Supervision

- s(39) WHS Regulations – Duty to Provide Adequate Information, Training and Instruction

- s(203) WHS Regulations – Management of Risks to Health and Safety (PCBUs with management or control of plant)

The Code of Practice “Managing risks of plant in the workplace” states that employers (PCBUs) must provide workers with information, training, and instruction as necessary to protect them from risks arising from the use of the plant.

FAQ’s

What is a scraper?

A scraper is a large piece of heavy-duty earthmoving equipment with a hopper (bowl) and a sharp horizontal front edge used for scraping and moving large amounts of soil, sand, and aggregate in bulk.

What is a scraper used for?

Scrapers are primarily utilised for large-scale grading and landscaping, mining, road construction, and agricultural tasks.

What hazards are involved in scraper use?

Some hazards that are involved in scraper use include:

- Overturns

- Collisions

- Dust

- Noise

- Crushing

What are some safety controls that can be utilised during scraper use?

Some safety controls that can be utilised include:

- Operator training

- Signaling

- Dust suppression

- Wearing PPE

- Regular maintenance

Did you know?

One of the more advanced developments in scraper technology is the advent of GPS and laser-guided control systems, which allow for precise leveling and grading to exact specifications with minimal passes, saving time and fuel. Autonomous or semi-autonomous scrapers are also being trialled in some large mining and construction projects, promising a future where these massive machines can operate with minimal human intervention, thus enhancing safety and efficiency on a grand scale.

Article Sources and Further Reading

- Model Code of Practice: Managing risks of plant in the workplace (Safe Work Australia) <https://www.safeworkaustralia.gov.au/doc/model-code-practice-managing-risks-plant-workplace>

- Plant (Safe Work Australia) <https://www.safeworkaustralia.gov.au/safety-topic/managing-health-and-safety/plant>

- The Complete Guide to WHS Policies and Procedures in Australia (Spire Safety) <https://spiresafety.com.au/resources/guide-to-whs-policies-and-procedures/>

- What is a PCBU? (Spire Safety)<https://spiresafety.com.au/resources/what-is-a-pcbu/>