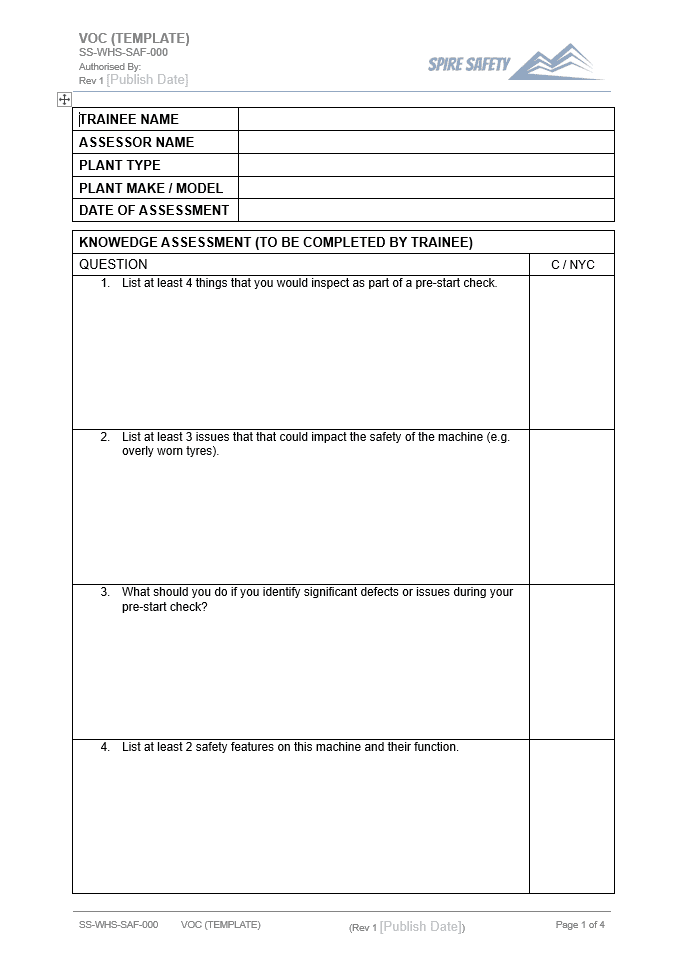

Free Bench Grinder VOC (Verification of Competency) Template

Download our free Bench Grinder VOC Template:

*For internal use only. Not for resale or redistribution. By downloading, you agree to our Free Resources Licensing Agreement.

Purpose of a Bench Grinder VOC Document

Bench grinder VOCs are used to verify a worker’s competence in bench grinder use. The primary goal is to protect workers from injury or illness through effective training and competency procedures. This form is broadly aligned with AS45001:2018.

How to Use

This Bench Grinder VOC should be completed by a competent person in consultation with the trainee who will use the plant.

This document is a template only and it must be customised for your business. Other aspects that may need to be considered include, but are not limited to, ensuring that:

- Relevant legal requirements have been met,

- Workplace specific risks are identified and managed, and

- Workers are consulted with during the customisation / review process.

When to Use

Bench grinder VOCs should be completed prior to the worker operating plant or equipment within your business.

Who Should Use

Bench grinder VOCs must be completed by someone who is familiar with operation of the piece of plant or equipment. This person should also be competent in training and assessment methods.

Legal Considerations

There is no specific legal requirement to complete a documented Verification of Competency (VOC). However, it is best practice. Completing a thorough Verification of Competency can help meet general legal duties, including:

- s(19)(3)c WHS Act – Duty to Provide Safe Systems of Work

- s(19)(3)d WHS Act – Duty to Ensure Safe Use of Plant

- s(19)(3)f WHS Act – Duty to Provide Adequate Information, Training, Instruction and Supervision

- s(203) WHS Regulations – Management of Risks to Health and Safety (PCBUs with management or control of plant)

The Code of Practice “Managing risks of plant in the workplace” states that employers (PCBUs) must ensure workers are trained and have the appropriate skills to carry out a particular task safely.

FAQ

What is a bench grinder?

A bench grinder is a stationary power tool used primarily for sharpening, shaping, and polishing metal tools, blades, and other objects. It consists of one or two rotating abrasive wheels mounted on a benchtop or pedestal, with a motor driving the rotation. Bench grinders are commonly used in metalworking, woodworking, and mechanical workshops for tasks such as sharpening chisels, knives, drill bits, and mower blades, as well as removing rust or burrs from metal surfaces. They are versatile tools for maintaining cutting edges and achieving precise finishes on metalwork.

What is a bench grinder used for?

A bench grinder is primarily used for sharpening, shaping, and polishing metal tools, blades, and other objects. It typically consists of one or two grinding wheels mounted on a benchtop or pedestal, which rotate at high speeds to grind away material from the workpiece. Bench grinders are commonly used in workshops, garages, and metalworking shops for tasks such as sharpening chisels, drill bits, and knives, removing rust or burrs from metal surfaces, and shaping metal parts to precise dimensions. They are versatile tools for maintaining and shaping metal objects with precision and control.

What hazards are involved in bench grinder use?

Many hazards exist in bench grinder operation, for example:

- Contact with Grinding Wheel

- Struck-By Accidents

- Electrocution

- Kickback

- Noise Exposure

- Eye Injuries

To mitigate these hazards, proper training, adherence to safety protocols, regular equipment maintenance, use of personal protective equipment (PPE), and thorough site inspections are essential.

Do you need training to operate a bench grinder?

In general, the level of training provided to workers must take into consideration “the nature of the work, the nature of the risks and the control measures required” – WHS regulations s(39). That is, for plant that poses no or minimal risks, there may be very little training required. As the risks of the plant increases, the requirement for training also increases.

To demonstrate competence in bench grinder operation, workers can complete the RTO unit https://training.gov.au/Training/Details/RIICRC319E.

Did You Know?

Did you know that bench grinders have a rich historical background? These powerful tools, which consist of a motor and abrasive wheels mounted on a bench or work table, have been used since the late 19th century. Originally developed for sharpening tools and blades, bench grinders quickly found their way into various industries and workshops, becoming integral equipment for tasks like metalworking, shaping, and polishing. Today, bench grinders continue to be widely used, combining the benefits of precision and versatility in countless applications.

Article Sources and Further Reading

- Model Code of Practice: Managing risks of plant in the workplace (Safe Work Australia) <https://www.safeworkaustralia.gov.au/doc/model-code-practice-managing-risks-plant-workplace>

- Plant (Safe Work Australia) <https://www.safeworkaustralia.gov.au/safety-topic/managing-health-and-safety/plant>

- What is a PCBU? (Spire Safety) <https://spiresafety.com.au/resources/what-is-a-pcbu/>