FREE HDPE Butt Fusion SOP (Safe Operating Procedure) Template

Download our free HDPE Butt Fusion SOP Template:

*For internal use only. Not for resale or redistribution. By downloading, you agree to our Free Resources Licensing Agreement.

Purpose of Document

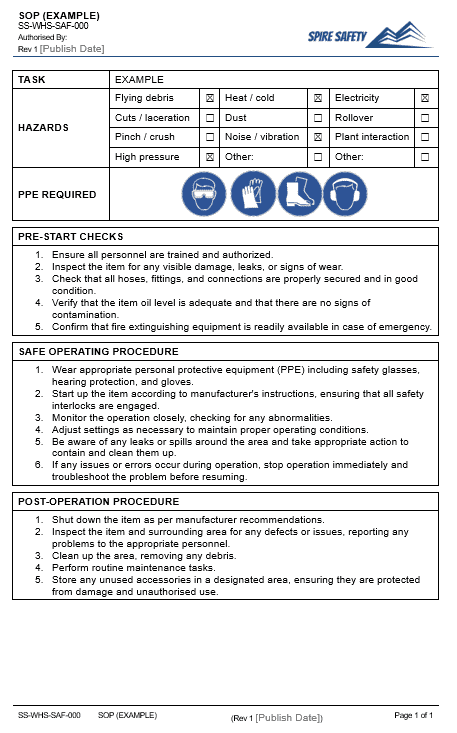

HDPE (High-Density Polyethylene) butt fusion SOPs outline a safe operating procedure for HDPE butt fusion use. HDPE Butt Fusion SOPs can also be used as a training and induction document. The primary goal is to protect workers from injury or illness by outlining a safe system of work and providing adequate training and instruction. This form is broadly aligned with AS45001:2018.

How to Use

This HDPE Butt Fusion SOP should be communicated to workers before they complete the task. A hard copy can also be displayed in the workplace or provided at the workface. You can also use this document during the induction or onboarding process.

NOTE: This document is a template only and it must be customised for your business. Other aspects that need to be considered include, but are not limited to, ensuring that:

- Relevant legal requirements have been met,

- Workplace specific risks are identified and managed, and

- Workers are consulted with during the customisation / review process.

When to Use

Workers should read and agree to comply with HDPE Butt Fusion SOPs prior to operation within your business. They can also be used for refresher training periodically.

Who Should Use

HDPE butt fusion SOPs should be developed by a competent person. The SOP is then read and followed by the worker completing the task. New workers should also read and understand the SOPs during the induction or onboarding process.

Legal Considerations

There is no specific legal requirement to have a documented Safe Operating Procedure (SOP). However, it is best practice, as having SOPs can assist in meeting general legal duties, including:

- s(19)(3)c WHS Act – Duty to Provide Safe Systems of Work

- s(19)(3)d WHS Act – Duty to Ensure Safe Use of Plant

- s(19)(3)f WHS Act – Duty to Provide Adequate Information, Training, Instruction and Supervision

- s(39) WHS Regulations – Duty to Provide Adequate Information, Training, and Instruction

- s(203) WHS Regulations – Management of Risks to Health and Safety (PCBUs with management or control of plant)

The Code of Practice “Managing risks of plant in the workplace” states that employers (PCBUs) must provide workers with information, training, and instruction as necessary to protect them from risks arising from the use of the plant.

FAQ’s

What is HDPE butt fusion?

HDPE butt fusion is a method used to join two pieces of high-density polyethylene (HDPE) pipes together by heating the ends of the pipes and then pressing them together to create a seamless joint.

What is HDPE butt fusion used for?

It’s primarily used in the construction and maintenance of pipelines for water, gas, and other fluids, ensuring leak-proof connections.

What hazards are involved in using HDPE butt fusion machines?

Some hazards that are involved in HDPE Butt Fusion use include:

- Heat-related injuries

- Burns

- Inhalation of fumes

- Ignition of combustible materials

What are some safety controls that can be utilised during HDPE butt fusion machine use?

Some safety controls that can be utilised include:

- Operator training

- Wearing PPE

- Ensuring adequate ventilation

- Using away from flammable materials and sources of ignition

Did you know?

HDPE (High-Density Polyethylene) butt fusion welding is a specialized technique crucial in joining HDPE pipes and fittings. Developed in the mid-20th century, butt fusion welding involves heating the ends of two HDPE pipes or fittings until they reach a molten state. Once heated, the ends are pressed together and allowed to cool, forming a permanent, homogeneous bond. This method ensures leak-proof joints ideal for various applications, including water and gas distribution, sewage systems, and industrial piping. HDPE butt fusion welding offers advantages such as excellent joint strength, corrosion resistance, and durability, making it a preferred choice in modern pipeline construction and maintenance.

Article Sources and Further Reading

- Model Code of Practice: Managing risks of plant in the workplace (Safe Work Australia) <https://www.safeworkaustralia.gov.au/doc/model-code-practice-managing-risks-plant-workplace>

- Plant (Safe Work Australia) <https://www.safeworkaustralia.gov.au/safety-topic/managing-health-and-safety/plant>

- The Complete Guide to WHS Policies and Procedures in Australia (Spire Safety) <https://spiresafety.com.au/resources/guide-to-whs-policies-and-procedures/>

- What is a PCBU? (Spire Safety) <https://spiresafety.com.au/resources/what-is-a-pcbu/>