What is a Principal Contractor and What Are Their Legal Duties?

What is a Principal Contractor?

A PC / Principal Contractor is a person (business owner) or company that is in charge of a construction project valued at over $250,000. This value differs in some states:

- Victoria – $350,000

- South Australia – $450,000

- Northern Territory – $500,000

For example, a residential building company that is building a house. The Principal Contractor may be appointed by the client, however if the project sum is over $250,000 (for most states) then appointing of a Principal Contractor is not necessary and the construction company will, by default, be a Principal Contractor under the WHS Regulations.

Generally speaking, the role of the Principal Contractor includes coordinating subcontractors, ensuring safety measures are in place and managing WHS issues on site.

Principal Contractor’s WHS Duties

The PCs role is to plan, coordinate, and manage the construction work to ensure that it is carried out safely. This includes ensuring that workers are trained, supervised, and provided with PPE.

The PC has legal duties to provide oversight and ensure subcontractors comply with their legal obligations. For example, the Principal Contractor must ensure that the subcontractor completes a Safe Work Method Statement (SWMS) for high-risk construction work.

The PC has legal duties to provide oversight and ensure subcontractors comply with their legal obligations. For example, the Principal Contractor must ensure that the subcontractor completes a Safe Work Method Statement (SWMS) for high-risk construction work.

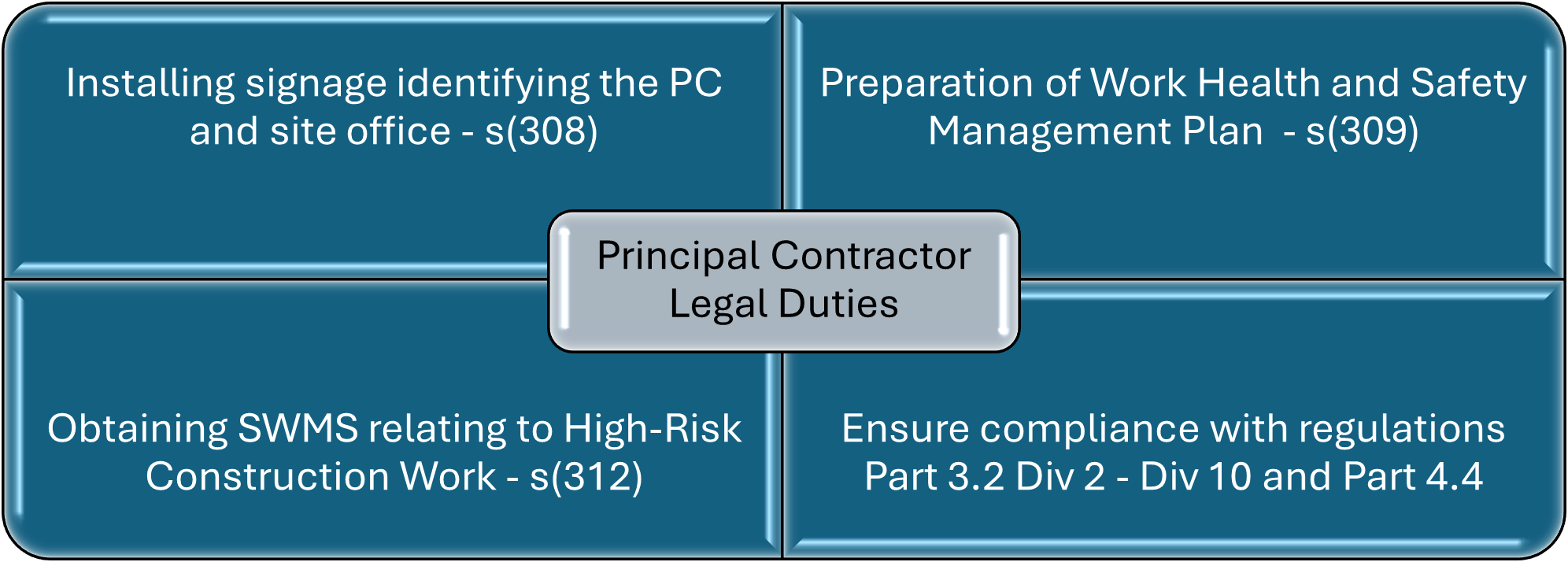

Legal Duties of a Principal Contractor

The legal obligations of a Principal Contractor under the Work Health and Safety Regulations (2011), include developing a Health and Safety Management Plan, collecting SWMS and ensuring WHS compliance on site.

The duties of a Principal Contractor are outlined in the WHS Regulations (2011):

S(308) – Installing signage identifying the PC and site office

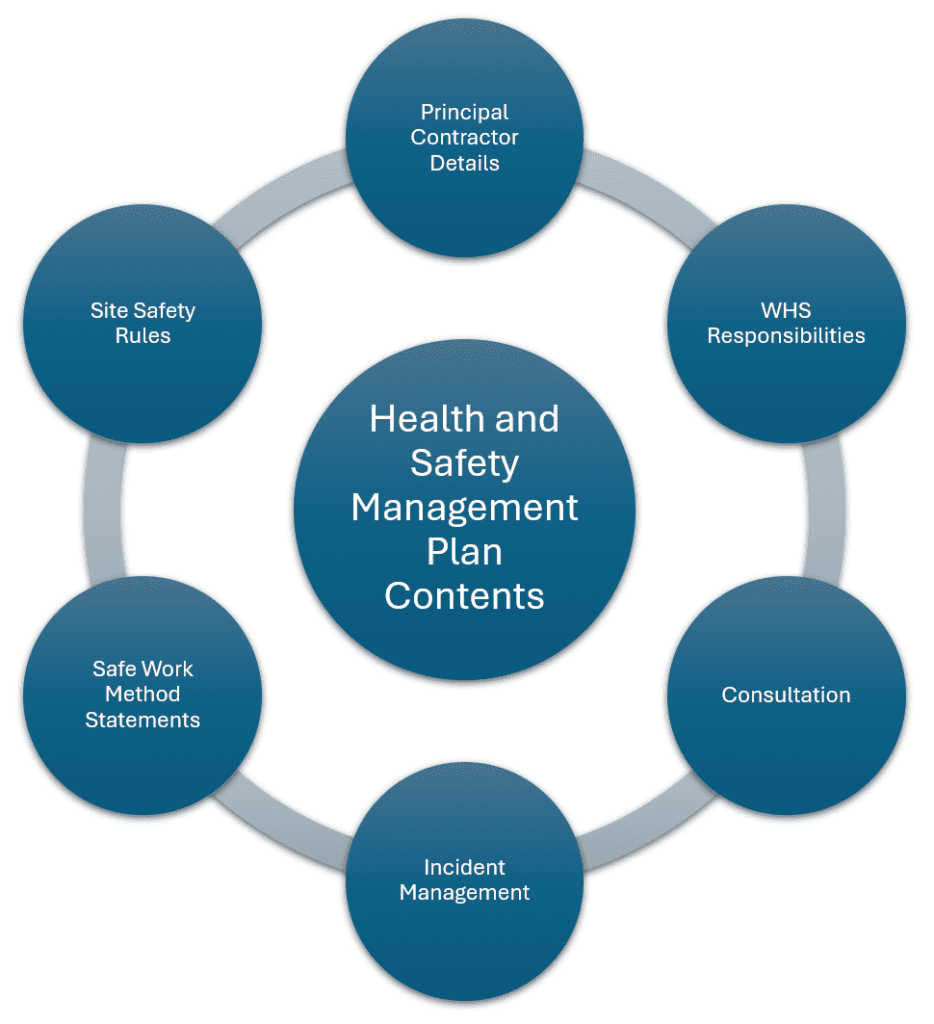

S(309) – Preparation of Work Health and Safety Management Plan that includes:

- the names, positions and health and safety responsibilities of all persons at the workplace

- the arrangements in place for consultation, cooperation and coordination between parties

- the arrangements in place for managing any work health and safety incidents that occur

- any site-specific health and safety rules

- the arrangements for the collection and any assessment monitoring and review of safe work method statements.

S(312) – Obtaining Safe Work Method Statements relating to High-Risk Construction Work

S(314) The contractor must put in place arrangements to ensure compliance with:

- Part 3.2 Div 2 – General Work Environment (layout, lighting, safe access etc.)

- Part 3.2 Div 3 – First Aid

- Part 3.2 Div 4 – Emergency Response

- Part 3.2 Div 5 – PPE

- Part 3.2 Div 7 – Risks from Airborne Contaminants

- Part 3.2 Div 8 – Hazardous Atmospheres

- Part 3.2 Div 9 – Storage of Flammable or Combustibles

- Part 3.2 Div 10 – Falling Objects

- Part 4.4 – Falls

Managing Shared Duties

The Principal Contractor shares duties with the subcontractor PCBU (or or company). Where shared duties exist, each person must discharge their duty to the extent to which they have the capacity to influence and control the matter (s16(3)(b) WHS Act) i.e. the more control and influence the PCBU has over the work, the more responsibility they have. Consider the following examples:

- A construction company engages a contractor to use the company’s earthmoving machines. The contracted worker rolls the machine and is fatally wounded.

- A construction company engages a marine diving company to complete subsea works. One of the divers has an equipment malfunction and dies.

In the first example, the construction company has more control over the situation as the contracted worker is using one of the company’s machines to do a job the company is familiar with. While in the second example the diver is using their own company’s gear to do a job that is extremely specialised. In the first example, the principal contractor has much more “influence and control” over the situation, resulting in a higher level of care required.

Health and Safety Management Plans

Health and Safety Management Plans are documents which provide an overview of how the PC manages safety on the construction site. Generally, a Health and Safety Management Plan will include the following:

Download our free Health and Safety Management Plan template.

Download our free Health and Safety Management Plan template.

*For internal use only. Not for resale or redistribution. By downloading, you agree to our Free Resources Licensing Agreement.

This document is a template only and it must be customised for your business. Other aspects that may need to be considered include, but are not limited to, ensuring that:

Relevant legal requirements have been met,

Workplace specific risks are identified and managed, and

Workers are consulted with during the customisation / review process.

Consultation and Collaboration

A key WHS obligation of a Principal Contractor is to consult and collaborate with other duty holders to ensure the safety of all workers. This involves regular communication and close coordination with subcontractors, designers, and clients to identify potential hazards and implement controls. Some examples of consultation methods include:

- Pre-Start Safety Meetings

- Toolbox Talks / Safety Meetings

- Safety Notice Boards

- Emails and Memos

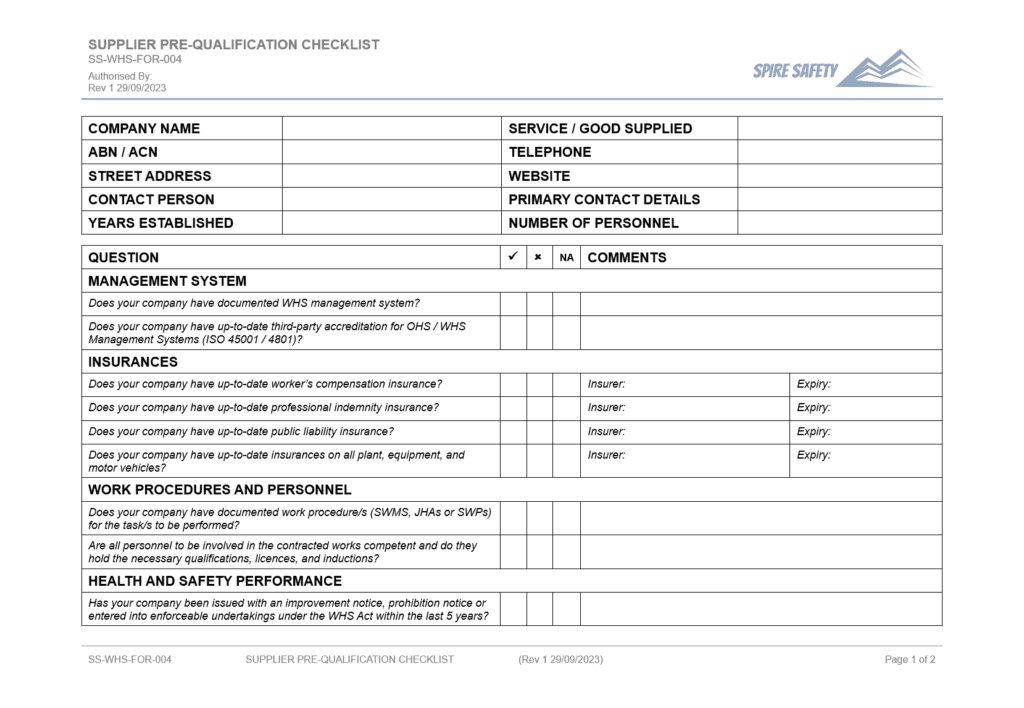

Engaging Subcontractors

When engaging subcontractors, the Principal Contractor must take reasonable steps to ensure the safety of the contractor. Read our guide on Contractor Management Procedures. This includes a free sub-contractor pre-qualification checklist, which can help manage your legal duties relating to subcontractors.

The PC should ensure the subcontractor is insured, licensed and competent.

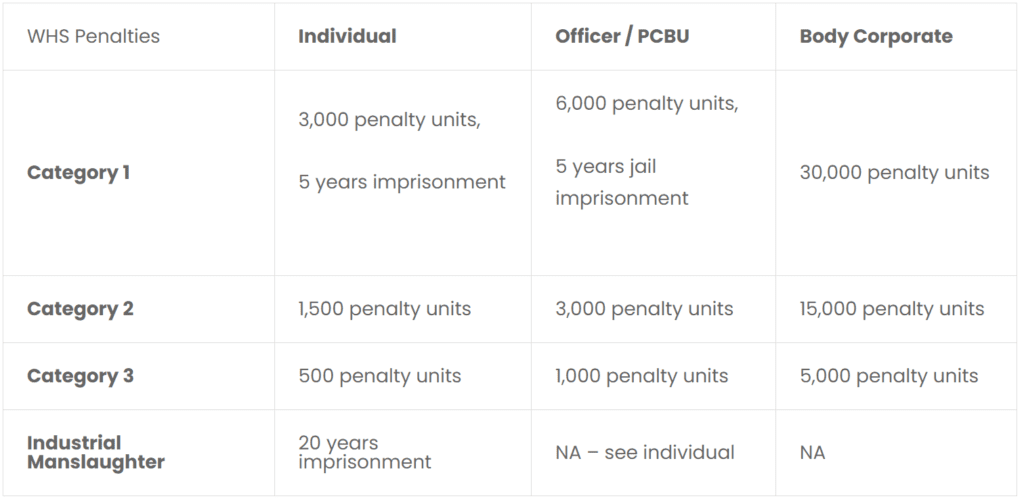

Penalties for Non-Compliance with WHS Obligations

For minor and first offences, the penalty is usually in the form of a Notice.

Improvement Notice

This document is issued by a government safety inspector and details a suspected contravention of the Act or Regulations. It contains information about who is required to address the issue and when it needs to be addressed. This is the least serious of the WHS penalties, however, the breach must still be rectified.

Prohibition Notice

Like an Improvement Notice, this is issued by a government safety inspector and details a suspected contravention of the Act or Regulations, however, a prohibition notice (as the name implies) prohibits the work activity from being completed until the legislative breach is rectified.

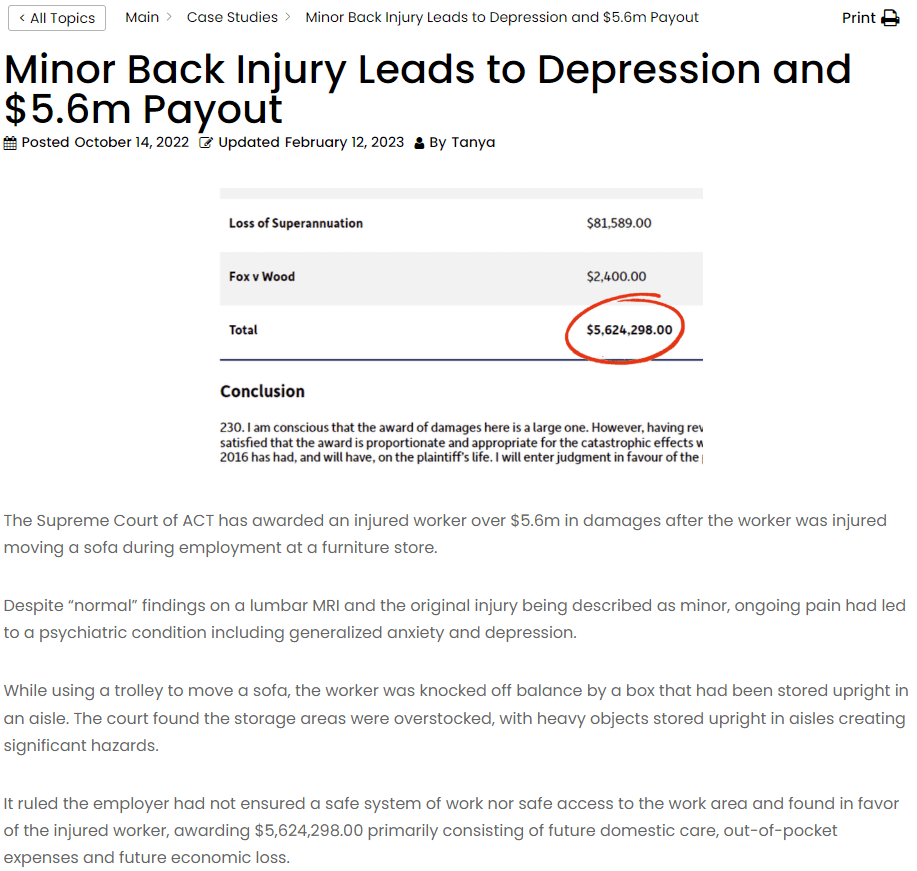

More serious penalties for non-compliance vary depending on the nature of the breach, but can include fines and even imprisonment. Read our article on WHS penalties for non-compliance.

We also publish case studies of recent court cases.

We also publish case studies of recent court cases.

FAQs

Are Principal Contractors responsible for their subcontractors?

To the extent that you have control or influence over the subcontractor, yes – you are partially responsible for their safety. You can manage this by:

- Completing a subcontractor pre-qualification

- Ensure SWMS are developed and implemented

- Providing oversight and supervision

How is a Principal Contractor different from a subcontractor?

A Principal Contractor is responsible for the whole construction project, whereas the subcontractor is only responsible for their portion of works.

Further Reading

What is a WHSMS (Work Health and Safety Management System)? (Spire Safety) <https://spiresafety.com.au/resources/what-is-a-whsms/>

What is ISO 45001 Certification and How Do I Get Certified? (Spire Safety) <https://spiresafety.com.au/resources/iso-45001-certification/>

What are the WHS Penalties for Non-Compliance? (Spire Safety) <https://spiresafety.com.au/resources/whs-penalties-for-non-compliance/>

Work Related Deaths Per Year in Australia: Facts and Figures (Spire Safety) <https://spiresafety.com.au/resources/work-related-deaths-per-year/>

Workplace health and safety management system (Comcare) <https://www.comcare.gov.au/safe-healthy-work/healthy-workplace/whs-system>