Mine Safety Management Systems

Mine Safety Management Systems (or Mining Safety Management Systems) are becoming a common legal requirements in many states, including New South Wales and Western Australia. Not just for large scale and complex mines, but also for smaller scale operations and even quarries.

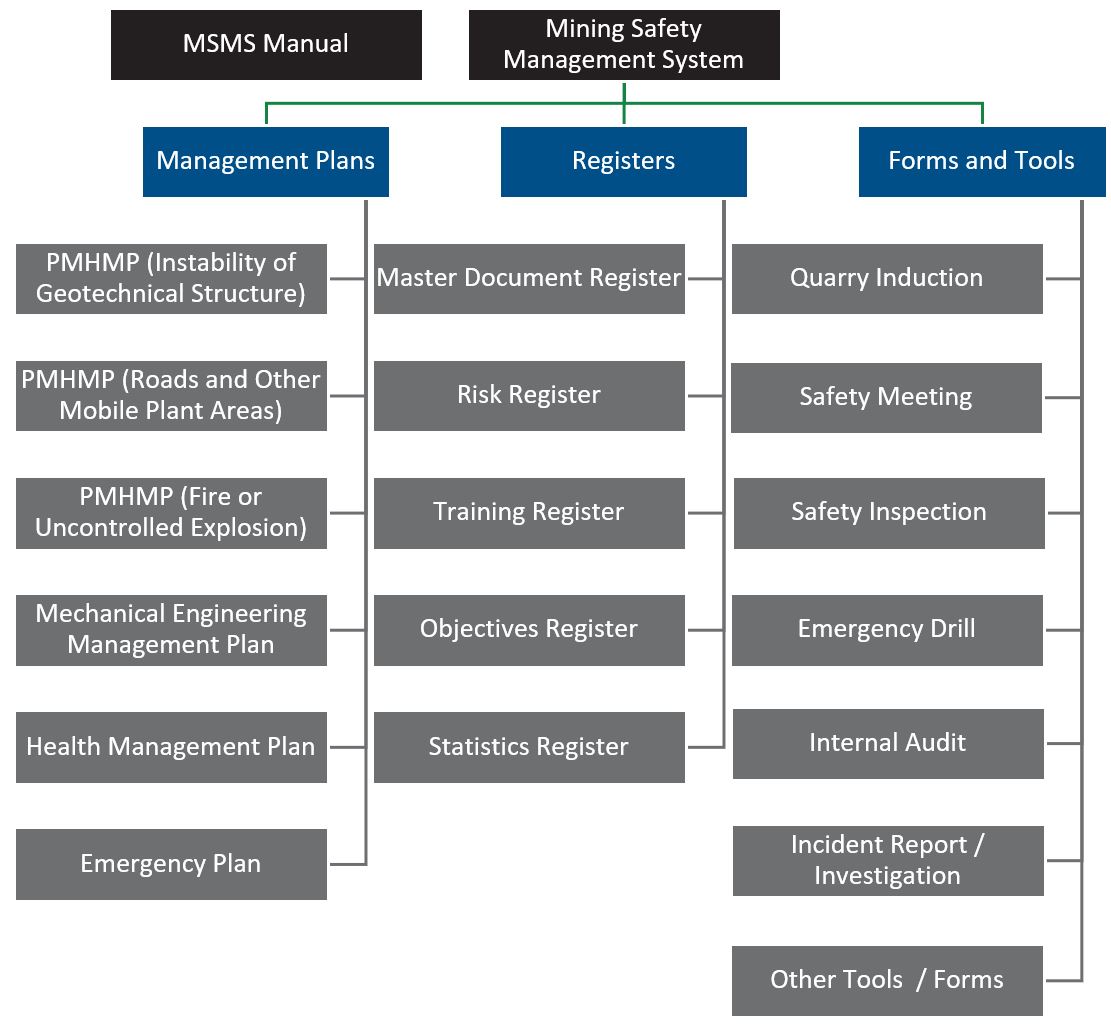

A Mine Safety Management System is a set of documents which outline how safety is managed on a mine site. These documents include a Manual, Policies & Procedures, Registers and Forms & Tools as well as mine-specific documentation, including Principal Mining Hazard Management Plans and Principal Control Plans.

If you need a Mine Safety Management System developed, contact us.

What is a Mine Safety Management System?

Mine Safety Management Systems are designed to identify and control hazards, reduce the likelihood of accidents and incidents, and improve overall safety performance.

Safety Documentation

A Mine Safety Management System contains documentation which a describe how the organisation ensures the safety of the mine. Examples of safety documentation:

- Policies:

- Work Health and Safety

- Drug and Alcohol

- Fitness for Work

- Plans

- Principal Mining Hazard Management Plans

- Principal Control Plan

- Emergency Response Plans

- Procedures:

- Risk Management

- Subcontractor Management

- Manual Handling

- Registers:

- Master Document Register

- SDS Register

- Training Register

- Corrective Actions Register

- Form and Tools:

- Inductions

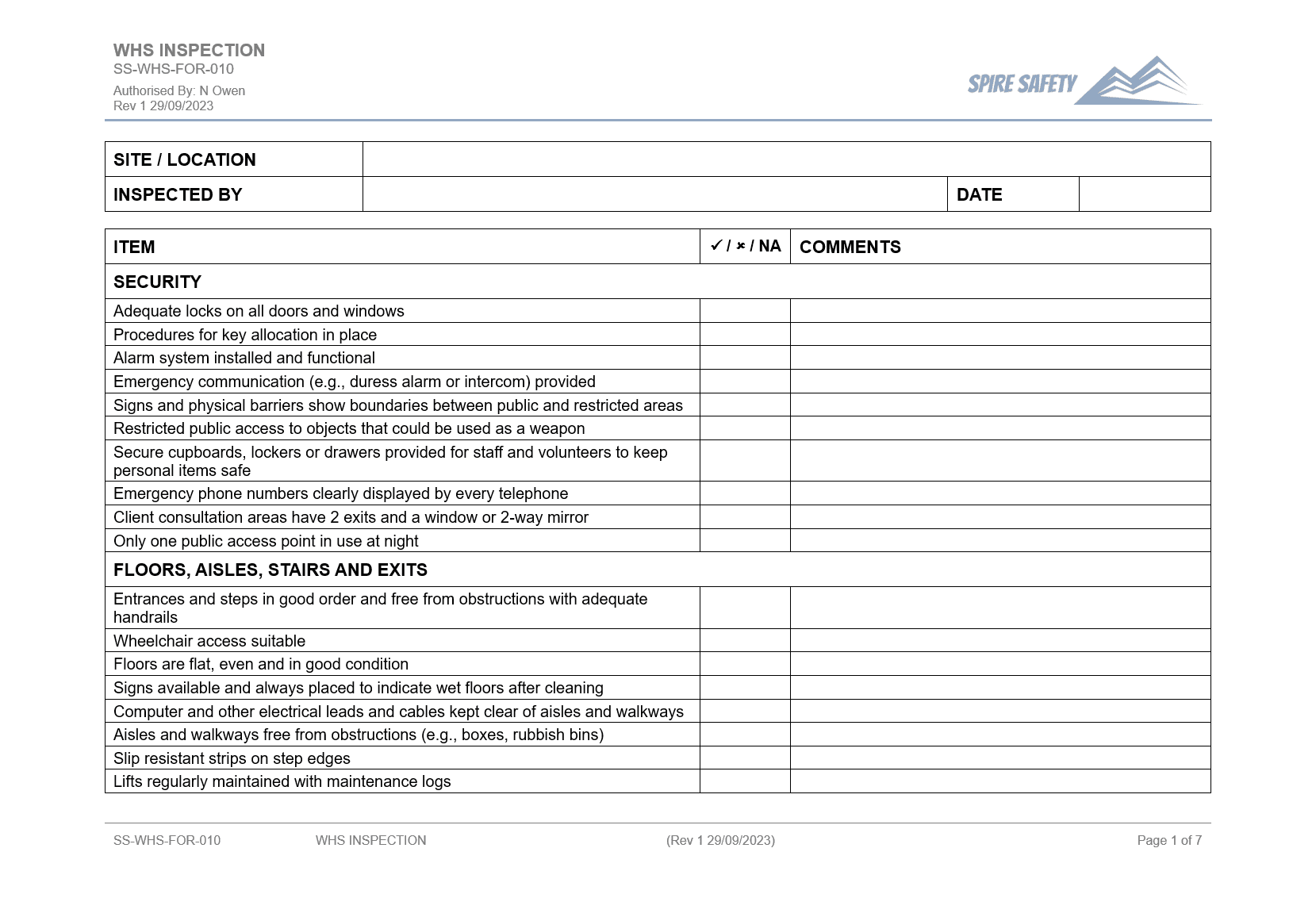

- Safety Inspections

- Safe Work Method Statements

- Safe Operating Procedures

Safety Policies

Safety Policies are usually short, overarching statements that guide an organization’s thinking, attitude, or values towards the management of safety risks.

Safety Plans

Safety Plans cover the safety management practices for a particular issue or site, for example an Emergency Response Plan or Site Safety Management Plan.

Safety Procedures

Safety Procedures are usually longer documents that give step-by-step guidance on how an organization manages safety issues, for example a First Aid Procedure or Risk Management Procedure.

Safety Registers

Safety Registers

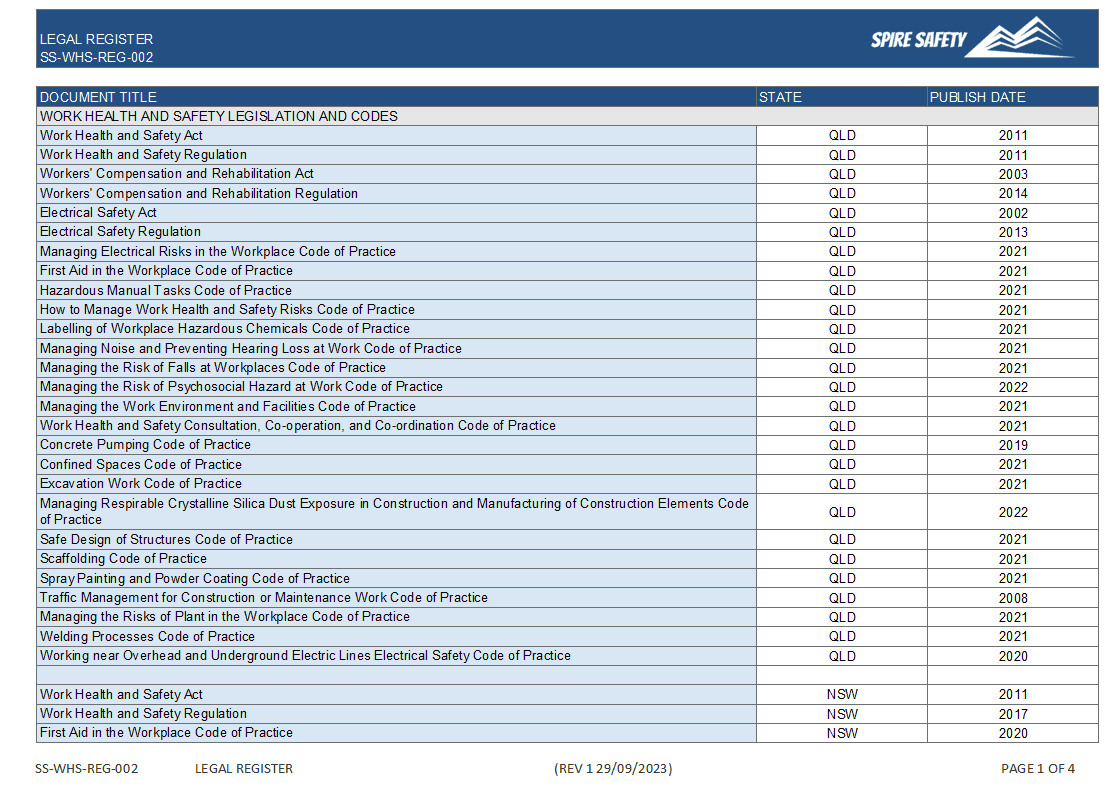

Safety Registers are usually excel spreadsheets that are used to organise, track or view data. For example, a Master Document Register tracks all the documents within a mine safety management system (as well as review dates and approvals).

Safety Forms and Tools

Safety Forms and Tools are the front-end documentation that are used by workers and managers to assist in managing safety. Examples include Safety Inductions, Inspections or Safe Work Method Statements (SWMS).

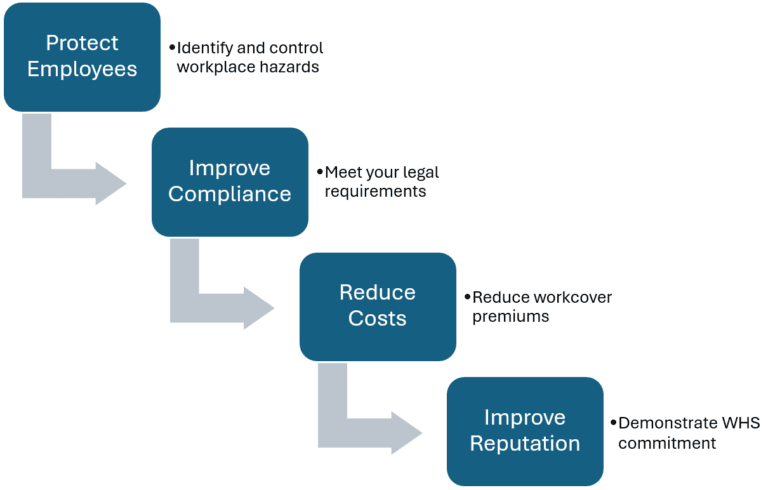

Benefits of a Mine Safety Management System

Mine Safety Management Systems protect workers and ensure a safe workplace. According to Safe Work Australia, the total cost of workplace injuries and illnesses in Australia in the 2017-18 financial year was estimated to be $61.8 billion, which represents 4.1% of the country’s GDP. This cost includes both direct and indirect costs, such as:

- Direct costs: Medical expenses, workers’ compensation payments, and the cost of replacing damaged equipment.

- Indirect costs: Lost productivity, absenteeism, and the cost of training replacement workers.

The WHSMS can also help boost a company’s reputation and help win larger contracts. Other reasons to have a Mine Safety Management System include:

Risk Management in a Mine Safety Management System

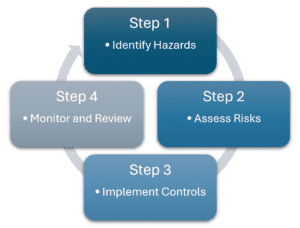

The code of practice “How to manage work health and safety risks” provides risk management requirements for business. In general, safety risk management has the following 4 steps:

Step 1 – Identify Hazards

Hazards can be identified by

- Consultation with:

- Workers,

- Managers,

- Contractors,

- Safety Inspections,

- Reviewing Acts, Regulations, Codes of Practice or WHS Alerts, and

- Incident Reports and Investigations.

Step 2 – Assess Risks

A risk matrix is used to assess the risk in terms of likelihood and consequence and scored from Low to Catastrophic.

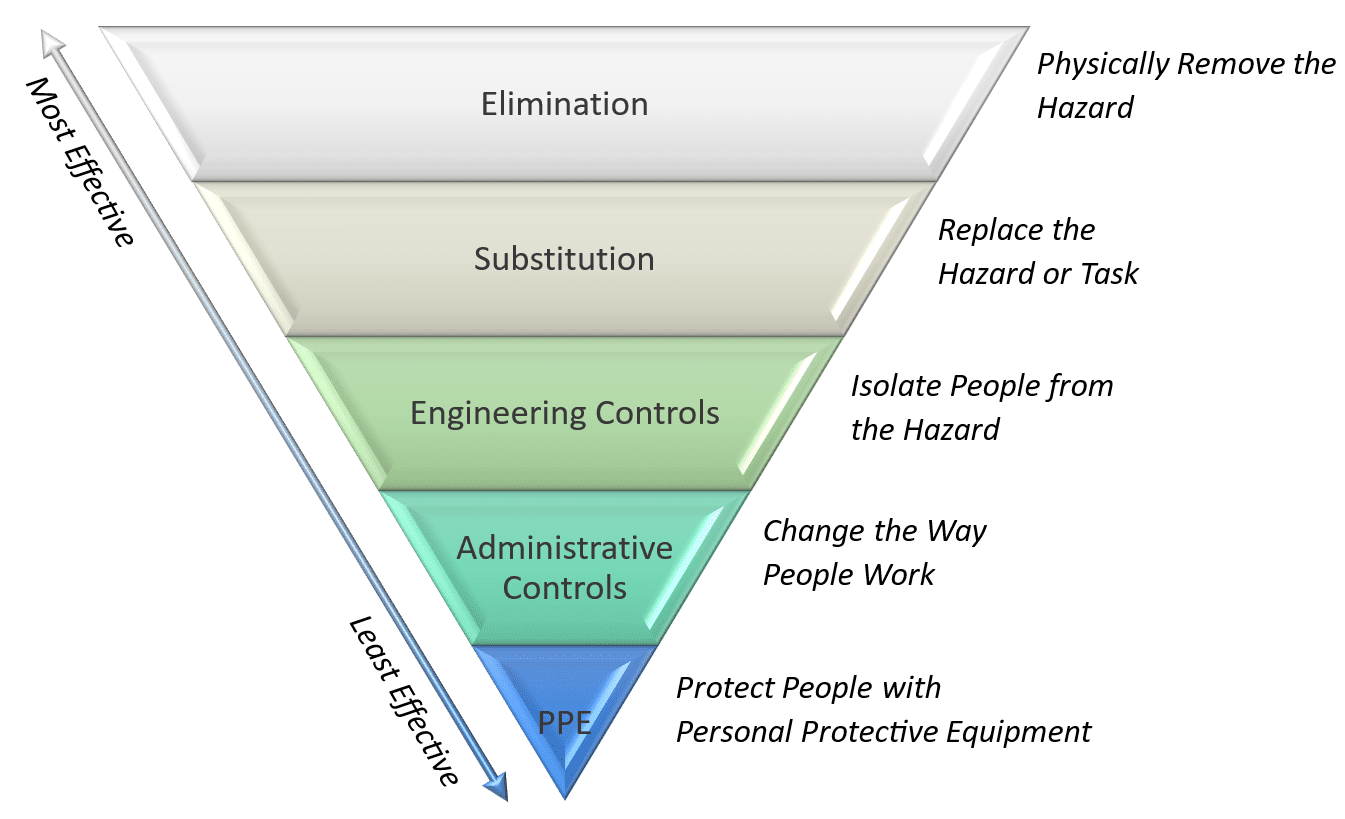

Step 3 – Implement Controls

Controls are ways that we can protect ourselves and others. Controls can be categorised in order of Most Effective to Least Effective (the hierarchy of controls).

Step 4 – Monitor and Review

Controls should be monitored and reviewed to ensure they remain effective. Controls can be monitored and reviewed by:

- Ongoing supervision,

- Consultation with workers,

- Safety inspections,

- Internal audits, and

- Analyzing incident and near-miss reports.

How to Develop a Mine Safety Management System

Conduct an assessment of workplace hazards to understand your risks. Review the relevant codes of practice and engage stakeholders, including workers, to develop policies and procedures. Finally implement these measures with effective communication, training, and monitoring processes to ensure continuous improvement.

To build your own Mine Safety Management System, check out our free resources:

- Free Policies

- Free Procedures

- Free Forms and Tools

- Free Plant Risk Assessments

- Free Verifications of Competency

Alternatively, to purchase our easy-to-use “off the shelf” WHSMS, contact us.

We help clients from any industry implement practical and cost-effective workplace safety solutions according to their individual needs. Our consultants are experts in their field and are committed to providing high-quality workplace safety services.

WHS Compliance Auditing

WHS Audits will help businesses determine what legal responsibilities are being met and what areas have gaps in safety management.

Our WHS Compliance Auditing service is designed to ensure your business not only meets but exceeds the rigorous standards set for workplace health and safety.

Through a comprehensive review of your current practices, policies, and procedures, we identify potential gaps in compliance and provide actionable recommendations to mitigate risks. Our expert team stays abreast of the latest regulations and industry best practices, offering you peace of mind that your operations are safeguarded against potential liabilities.

Partner with us to foster a safer work environment, enhance employee well-being, and secure your company’s reputation as a leader in health and safety excellence!

ISO Certification

Achieving ISO accreditation from an accredited certification is a vital ambition for corporations looking to demonstrate their commitment to HSEQ performance.

Our ISO Certification service is tailored to guide your business through the intricate process of achieving and maintaining ISO standards compliance.

By leveraging our deep understanding of the ISO framework and industry-specific requirements, we offer a structured approach to prepare your organization for certification. From initial gap analysis to implementing process improvements and conducting internal audits, our team supports you every step of the way.

Let us help you demonstrate your commitment to quality, sustainability, and continuous improvement, setting your business apart in the competitive landscape.

System & Procedure Development

Management systems and procedures outline how the business manages its responsibilities and document how critical functions are performed.

Our Safety System and Procedure Development service is meticulously crafted to build robust safety frameworks tailored to your organization’s unique needs.

Recognizing the critical importance of workplace safety, we work closely with you to develop and implement comprehensive safety systems and procedures that not only comply with regulatory standards but also promote a culture of safety and responsibility. From risk assessments and safety planning to training programs and emergency response strategies, our expert team provides end-to-end support.

By partnering with us, you empower your business to minimize risks, protect employees, and enhance operational efficiency!

WHS Training & Gap Analysis

Legally, staff must be trained and competent to perform their jobs. As a rule, the amount and level of training should be directly proportional to the safety risk involved with the job.

Our WHS Training and Gap Analysis service offers a dual approach to fortifying your workplace safety and compliance.

Starting with a thorough gap analysis, we meticulously evaluate your current WHS practices against industry standards and regulatory requirements, identifying areas for improvement and providing clear, actionable insights.

By choosing our service, you not only elevate your compliance and safety standards but also empower your employees with the knowledge and skills to maintain a safe working environment!

Other Safety Services & Advice

Spire Safety can provide experienced and qualified safety professionals wherever and whenever you need them.

Understanding that each business faces unique challenges, we provide Other Safety Services and Advice tailored to your specific requirements. Whether you need assistance with ergonomic assessments, chemical safety management, mental health initiatives, or any other safety concern, our expert team is equipped to deliver.

We offer practical advice, innovative strategies, and hands-on support to ensure your workplace not only meets safety regulations but becomes a benchmark for best practices in your industry.

Partnering with us means gaining access to a wealth of knowledge and experience, dedicated to enhancing the safety, well-being, and productivity of your workforce!

No matter the workplace, no matter the occupation, our consultants are passionate about providing quality advice to ensure the highest standard of compliance, safety culture and wellbeing within your organisation.

Our WHS services:

- WHS Compliance Auditing

- ISO Certification

- System and Procedure Development

- WHS Training and Gap Analysis

- Other Safety Services and Advice

We also offer engaging and interactive training programs suitable for a range of workplaces. All training is conducted by professionals, who are experts in their field and have the relevant training and assessing qualifications. Our training includes courses accredited by ASQA (Australian Skills Quality Authority) and non-accredited courses that can be tailored and specialised to meet our client’s needs.

The Australian Mining Challenge

Australia, a vast continent boasting abundant mineral wealth, is renowned for its mining industry. From the rich red soils of Western Australia’s Pilbara region, teeming with iron ore, to the goldfields and gemfields of Queensland and Victoria – mining is ingrained in the nation’s DNA. Yet, this industry, while contributing immensely to the country’s economy, is fraught with risks.

A Dangerous Pursuit

Mining, despite all the technological advancements, remains inherently perilous. The subterranean world is an unforgiving environment, where the slightest misstep can lead to disaster. The dangers include:

- Falls and Collapses: Mineshafts and tunnels are prone to collapses and falls, burying miners alive.

- Gas Hazards: Toxic gases, such as methane, can accumulate and cause explosions or suffocation.

- Equipment Mishaps: Heavy machinery accidents can lead to serious injuries or fatalities.

- Dust and Silica Exposure: Prolonged exposure to mining dust can lead to respiratory diseases.

- Heat Stress: Working in the depths of the earth can subject miners to extreme temperatures.

With these hazards in mind, it’s imperative to have a robust Mine Safety Management System Australia – Spire Safety Consultants are well-equipped to provide.

Spire Safety Consultants: Your Trusted Partner

When it comes to navigating the treacherous terrain of mine safety, you need a partner who understands the stakes. Spire Safety Consultants is that partner.

With years of experience and a dedicated team of experts, they’ve carved a niche in the industry as the go-to solution provider for all things related to mine safety management systems.

Expertise That Matters

Spire Safety Consultants have a team of experts who have spent years working in the mining industry. Their deep knowledge of the field enables them to offer practical, tailored solutions that work in the real world. They understand that safety isn’t just a matter of ticking boxes; it’s about ensuring every miner returns home safely, every day.

Cutting-Edge Technology

In a world where technology is evolving at a rapid pace, Spire Safety Consultants stay ahead of the curve. They employ the latest innovations to create a seamless and efficient mine safety management system. This not only enhances safety but also improves productivity, a win-win situation for everyone involved.

The Spire Safety Mine Safety Management System

So, what exactly does the Mine Safety Management System Australia – Spire Safety Consultants offer? Let’s take a closer look.

Comprehensive Risk Assessment

One of the first steps in ensuring mine safety is identifying potential risks. Spire Safety Consultants conduct thorough risk assessments to pinpoint hazards that might otherwise go unnoticed. This proactive approach is key to preventing accidents before they happen.

Customized Safety Plans

Every mine is unique, and so are its safety needs. Spire Safety Consultants understand this and create customized safety plans tailored to each mine’s specific requirements. This ensures that the safety system isn’t just a generic template but a finely tuned instrument.

Real-Time Monitoring

In the world of mine safety, every second counts. Spire Safety Consultants offer real-time monitoring solutions that allow you to keep a constant eye on safety parameters. This quick response system ensures that any potential issues are addressed promptly, minimizing the risk of accidents.

Training and Education

Knowledge is power, and Spire Safety Consultants empower your workforce with the knowledge they need to stay safe. They offer comprehensive training and education programs that equip miners with the skills to recognize and mitigate risks effectively.

FAQ

Q1: Why is a Mine Safety Management System necessary?

A Mine Safety Management System is essential to identify, assess, and control risks in the mining industry. It’s a proactive approach to prevent accidents and ensure the well-being of miners.

Q2: How do Spire Safety Consultants stand out from the competition?

Spire Safety Consultants distinguish themselves with their industry expertise, cutting-edge technology, and customized solutions that cater to the unique needs of each mine.

Q3: Is the Mine Safety Management System applicable to all types of mining operations?

Yes, Spire Safety Consultants tailor their system to suit all types of mining operations, from open-pit mines to underground tunnels.

Q4: What benefits can a mine expect from implementing the Spire Safety Consultants system?

Implementing Spire Safety Consultants’ system leads to enhanced safety, increased productivity, and a reduction in accidents, ultimately saving lives and resources.

Q5: Is Spire Safety Consultants’ system compliant with Australian safety regulations?

Absolutely! Spire Safety Consultants’ Mine Safety Management System complies with all relevant Australian safety regulations, ensuring legal compliance.

Conclusion

In the ever-evolving world of mining, safety remains paramount. The Mine Safety Management System Australia – Spire Safety Consultants offer is not just a system; it’s a lifeline for miners, a shield against the dangers that lurk beneath the earth’s surface.

With their expertise, cutting-edge technology, and commitment to customizing solutions, Spire Safety Consultants are changing the game. They’re making mining safer, one mine at a time, and ensuring that Australia’s mining industry continues to thrive without sacrificing the lives of its workforce.

In a world where risks are inherent, having a partner like Spire Safety Consultants is not just a choice; it’s a necessity.

So, as the earth yields its treasures, let’s ensure that the hands that extract them return safely to their loved ones, thanks to the vigilant watch of Mine Safety Management System Australia – Spire Safety Consultants!

List Of Australian Regulations Regarding Work Health and Safety (Mines) Regulations 2022

🗒️ Answer

The Australian regulations regarding Work Health and Safety (Mines) Regulations 2022 can be found in the following sources:

🌐 Sources

- Legislation Western Australia – Work Health and Safety (Mines) Regulations 2022

- This source provides information about the Work Health and Safety (Mines) Regulations 2022 in Western Australia.

- Department of Mines, Industry and Regulation Western Australia – Work Health and Safety (Mines) Regulations 2022 Comparison Table

- This source offers a comparison table that summarizes the similarities and differences between the Work Health and Safety (Mines) Regulations 2022.

- Legislation New South Wales – Work Health and Safety (Mines and Petroleum Sites) Regulation 2022

- This source contains information about the Work Health and Safety (Mines and Petroleum Sites) Regulation 2022 in New South Wales.

- Australasian Legal Information Institute – WORK HEALTH AND SAFETY (MINES) REGULATIONS 2022

- This source offers detailed information regarding specific regulations within the Work Health and Safety (Mines) Regulations 2022 in Western Australia.

Safety Registers

Safety Registers